Have You Been Troubled By Slow Drying Joint Compound?

Clean Electric Heaters are an ideal solution to speed up drying joint compound in cold weather.

If you hang sheetrock for a living you no doubt have been troubled by slow drying joint compound. Many factors can contribute to slow drying joint compound, including temperature and moisture. It seems a heavily debated issue, so what is the best method to control the building’s environment for optimal drying?

What are the ideal conditions?

The ideal environmental conditions for drying joint compound are a temperature range of 65 degrees to 80 degrees Fahrenheit and a relative humidity between 20 to 40 percent. The working space should be conditioned for a few days prior to the application of the joint compound, ideally with a warm, gentle breeze flowing through the area to remove excess humidity. At 70 degrees Fahrenheit and an RH of 30, joint compound under tape in a ventilated room will dry in approximately 12 hours. In that environment, you can walk away from a job at 3 p.m., and by 7 a.m. the following morning, the joint compound will be dry.

Drying Joint Compound with Electric Heaters.

Uncomplicated to use and easy to move, the simple cord and (typically) plug design means you can take the heater with you from location to location, giving you the flexibility of delivering Clean, Dry Air with No Emissions exactly where you need it, when you need it.

Clean Electric Heaters are an ideal solution to speed up drying joint compound in cold weather. Electric Heaters provide a specific level of heat during cold weather, and because electricity is totally dry do not add humidity to the air and do not require ventilation of hazardous fumes. Traditional methods often used were direct fired/open flame heaters that can create a harmful buildup of both carbon monoxide and carbon dioxide fumes and increase humidity levels. Carbon monoxide poisoning occurs from exposure to these gases in enclosed spaces, creating extreme hazards for all tradespeople. Adequate ventilation with fresh air must be provided to avoid this condition.

How much heat do I need? Target Temperature range of 65 degrees to 80 degrees Fahrenheit

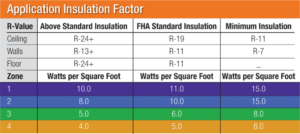

Depending on the insulation value of the space, electric heaters typically require between 5 watts – 15 watts per square foot. King offers many electric industrial portables that can plug directly into oven and dryer receptacle. Make sure to verify the plug configuration used is compatible with whatever your source power is compatible with.

Follow the below 4 steps to calculate the optimal heater size in watts per square foot.

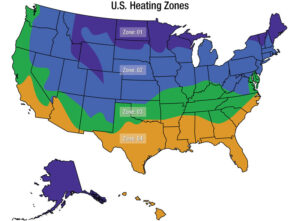

Step 1. Select the heating zone your space is located in

Step 2. Select the insulation values that best describes insulation used in your space

* Insulation is rated for a specific R-Value, the industry standards for effectiveness.

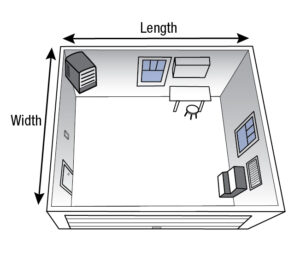

Step 3. Multiply length x width of your space to calculate total square feet.

Example 20’ L x 10’ W = 200 square feet

Step 4. Calculate the wattage requirement of the heater.

Multiple the total square feet by the watts per sqft based on the heating zone and your estimated insulation values (shown in the chart in step 2) to determine the correct wattage needed to heat your space. Select the Industrial Portable heater closest to this wattage.

Example: Zone 2, FHA Standard Insulation = 8 Watts per Sq Ft

8W per SqFt x 200 Square Feet = 1,600 Watts Required

Industrial Portable Unit Heater

This Industrial Portable Unit Heater is constructed to hold up to the rigorous demands of jobsites or industrial facilities.

Ducted Industrial Portable Heater

This Industrial Portable Unit Heater can be ducted, to direct the heated air to required areas and are idea

Electronic Industrial Portable

With in-built Platinum electronic thermostat for accuracy and remote control for simple operation.

Wheeled Portable Unit Heater

This wheeled portable unit heater is constructed to hold up to the rigorous demands of a jobsite or industrial facility.

Increase Air Circulation

The length of time it takes for mud to dry decreases when air is moving around the room rather than staying still. If it is not overly humid outside, open up the windows to circulate the air. However, if it is humid, avoid letting that humidity in, as it can actually slow the drying time. Set up fans in the room to get the air moving, whether or not you are able to open the windows.

High Velocity Air Circulator

Outdoor Rated Oscillating Air Circulators are a powerful commercial-grade solution for cooling workshops, warehouses, factories, gyms and more.

Wall Mount Air Circulator

Outdoor Rated Oscillating Air Circulators are a powerful commercial-grade solution for cooling workshops, warehouses, factories, gyms and more.

Tiltable Drum Fan

High Velocity Direct Drive Drum Fans are great for heavy duty air circulation in light duty commercial applications where an economical solution is needed.

Industrial Fixed Drum Fan

High Velocity Direct Drive Drum Fans are great for heavy duty air circulation in light duty commercial applications where an economical solution is needed.