The Best Approach

In bustling industrial environments—whether it’s a factory floor, warehouse, or workshop—excessive heat can severely impact employee comfort and productivity. Without full-scale climate control systems, strategically deployed high-velocity fans can help flush hot, stagnant air and usher in cooler air, making the space far more tolerable.

Step 1: Seal & Insulate the Structure

Before installing fans, optimize your building’s thermal envelope:

-

Wall & Roof Insulation: Warehouse and plant walls, especially older buildings, often lack adequate insulation. Upgrading to quality spray foam or rigid board insulation can significantly reduce heat gain.

-

Door Seals & Dock Areas: Ensure overhead doors, dock seals, and strip curtains are tightly sealed to prevent hot outdoor air infiltration and to maintain your airflow strategy’s efficacy.

Step 2. Use High-Velocity Fans Strategically

High-velocity fans are essential for pushing air across vast industrial spaces. King’s PFO and WFO high-velocity fans are built for demanding industrial environments—especially where airflow is needed in large open areas.

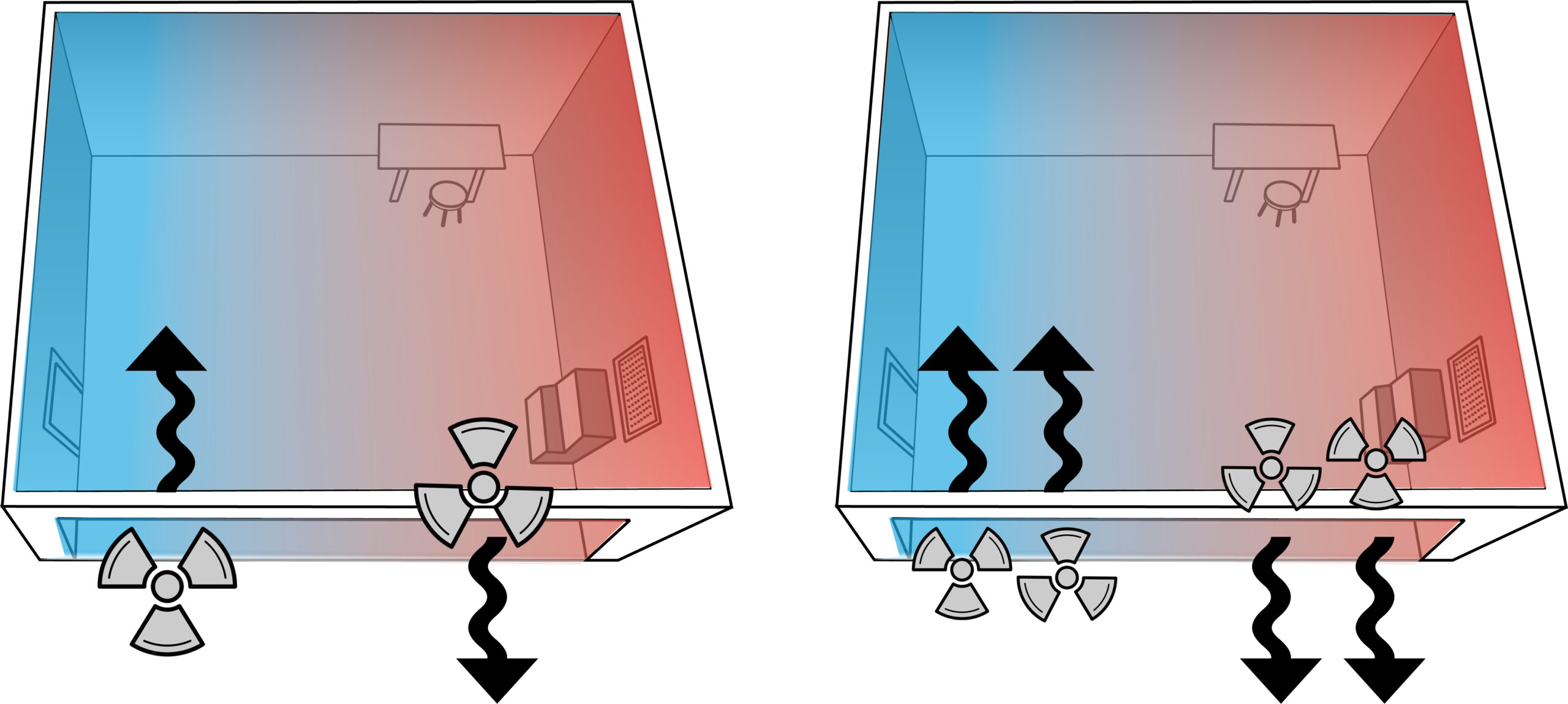

Option A. Exhaust + Intake Setup (Minimal Openings)

If your building has only one major opening—such as a dock door or roll-up bay—creating a balanced intake and exhaust system is critical. Relying on a single fan won’t be enough to cycle out the heat effectively.

-

Intake Fan (Low Position): Place this fan on the shaded side of the building, near the floor, where incoming air is cooler and denser. This helps introduce fresh, outside air into the space.

-

Exhaust Fan (High Position): Mount this fan high up on the opposite side of the space or near the ceiling above the main opening. Since hot air rises, placing the fan higher accelerates the removal of accumulated heat at ceiling level.

This creates a directed airflow path (“wind tunnel”) that systematically expels hot air while introducing cooler outside air—crucial during operations in tight indoor spaces, even in high external temperatures.

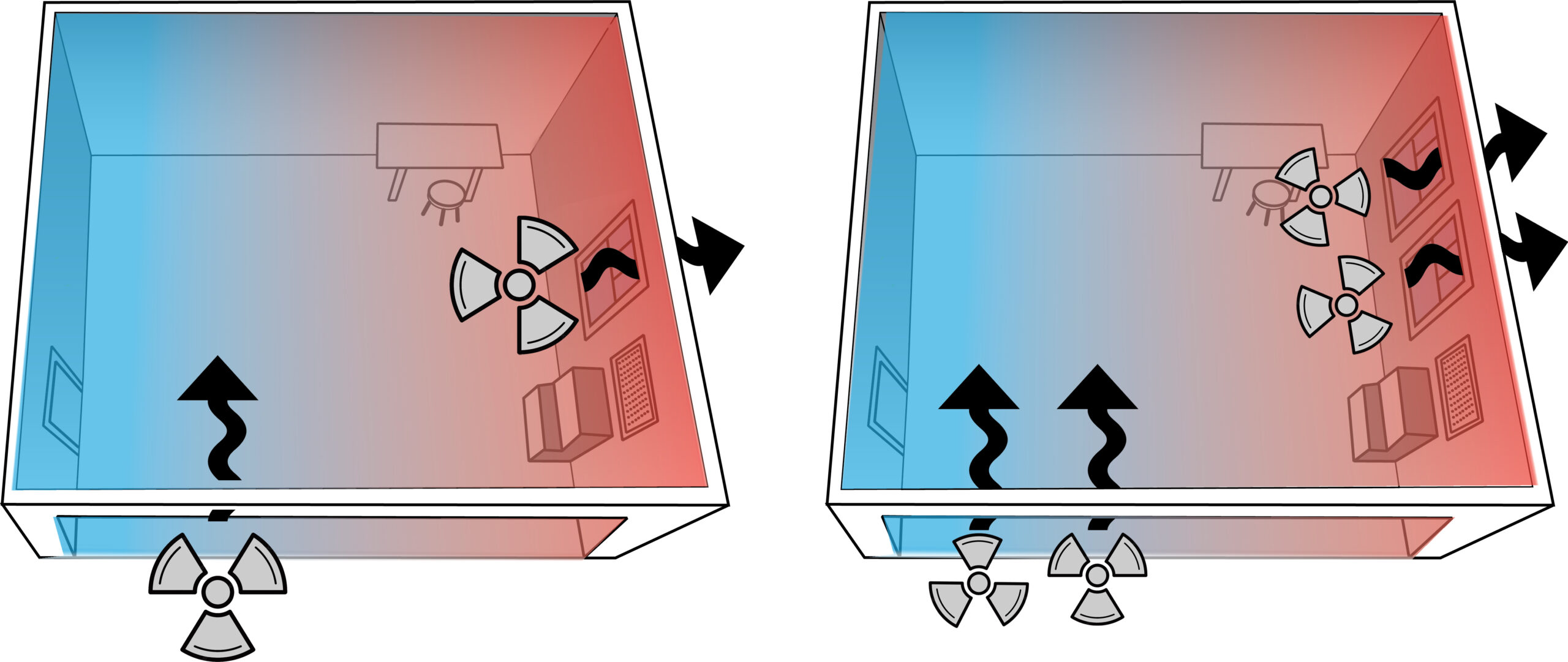

Option B. Exhaust + Intake Setup (with Windows)

If your facility has windows, louvered vents, or multiple access points, you’re in a much better position to effectively manage airflow compared to buildings with a single entry. The same core principle applies: bring cooler air in and push the hotter air out.

But don’t assume the largest opening is always the best spot for intake. Instead, place inward-blowing fans on the shaded side of the building where the incoming air will be cooler. Outward-blowing fans should be on the sun-exposed side to help expel the warmest air. If your main roll-up or dock door is under direct sun, consider raising it just enough to allow airflow—especially if the interior face is insulated. This can reduce the burden on your exhaust fan and improve overall efficiency.

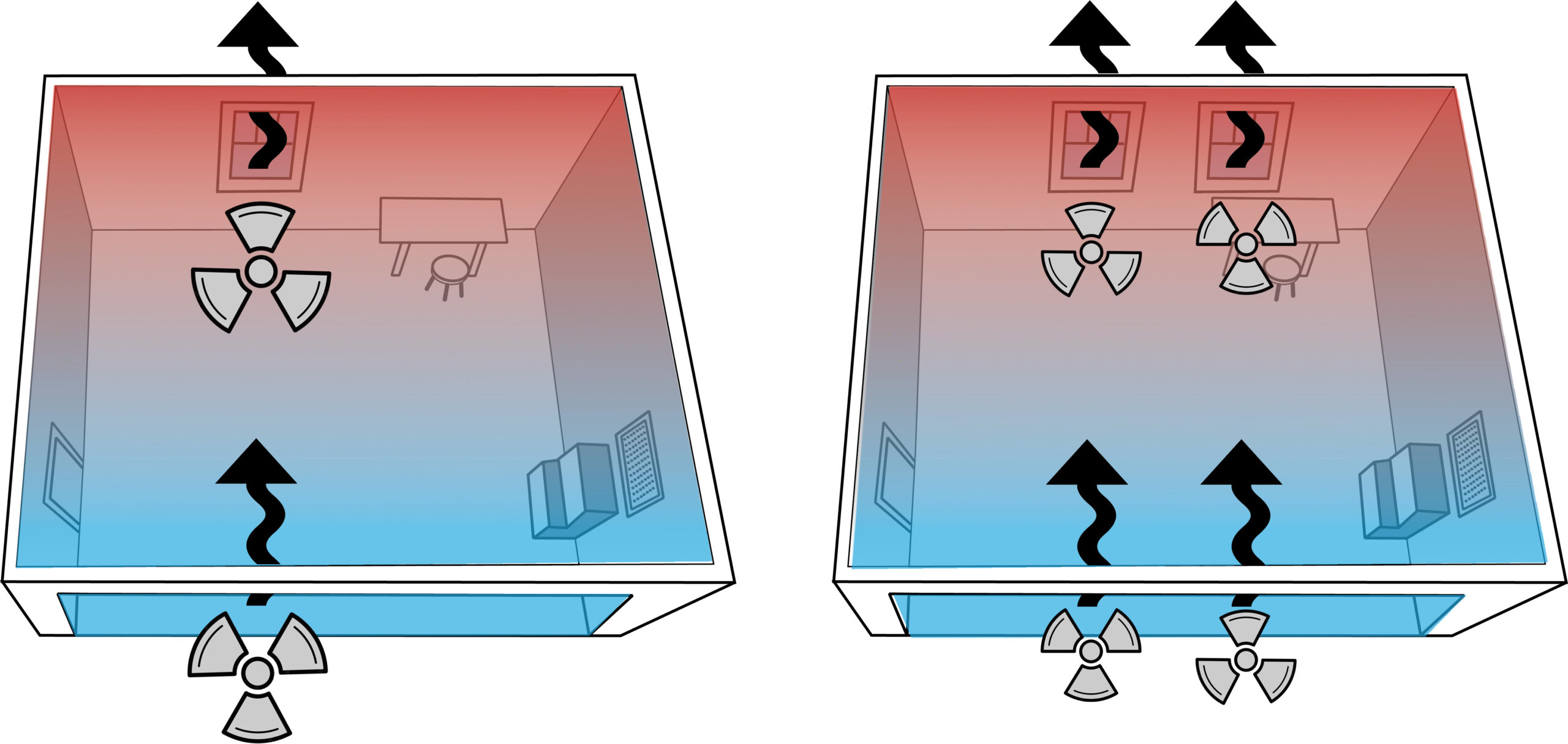

Option C. Ideal Exhaust + Intake Setup (Windows Opposite of Entry)

An ideal setup in an industrial space is to have a secondary opening—like a window, louvered vent, or overhead door—on the opposite side of your main entry. This allows you to create a strong cross-ventilation system using multiple high-velocity fans. Position intake fans low on the shaded side to pull in cooler air, and place exhaust fans high on the hot side to expel rising warm air. The greater the separation between intake and exhaust, both in height and distance, the more powerful and effective your fan-driven cooling system becomes.

Why It Works: Thermodynamics in Action

Even when outdoor temps are high, airflow helps cool workers through increased sweat evaporation. This “wind chill” effect is crucial in industrial settings, especially where full air conditioning isn’t feasible. Plus, moving air helps disperse dust and airborne contaminants, enhancing air quality.

Additional Efficiency Boosters

-

Shaded Intake Zones: Position inlets away from direct sunlight to reduce intake air temperature.

-

Dock Door Adjustments: Opening doors just enough to allow good airflow while minimizing heat gain is more effective than wide-open installations.

-

Routine Maintenance: Keep fan blades clean and ducts clear for optimal airflow. Check for obstructions at inlets and exhausts.

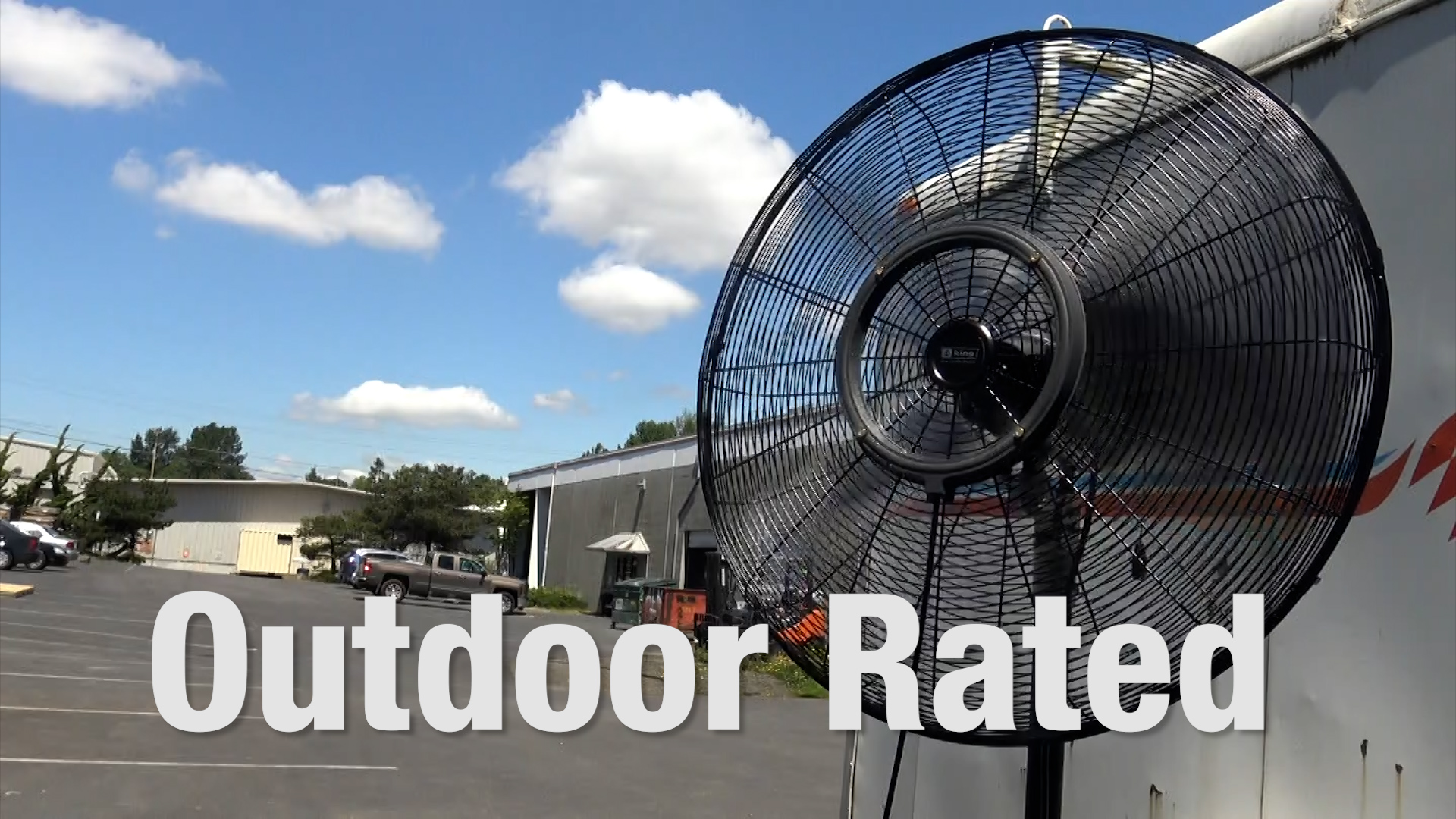

Outdoor-Rated & UL2021 Rain Tested

King’s PFO and WFO high-velocity fans are built for demanding industrial environments—especially where airflow is needed in partially open or outdoor-exposed areas like loading docks, warehouse bays, or open-air work zones. These fans are outdoor-rated and tested to the UL2021 Rain Test, ensuring they stand up to wet conditions. Their waterproof, totally enclosed motors are rated for wet locations and offer three speeds, making them a durable and versatile option for year-round industrial ventilation.

Add a PFO-MISTKIT

For even greater cooling power in industrial settings, consider upgrading with the PFO-Mist Kit, designed to work seamlessly with King’s PFO and WFO outdoor-rated high-velocity fans. This simple addition adds a fine mist to the airflow, dramatically improving evaporative cooling—ideal for loading docks, open-air workstations, or warehouse bays exposed to high temperatures. Whether you’re using a pedestal, floor, or wall-mounted model, the mist kit turns your fan into a powerful cooling solution for even the hottest industrial environments.