For hazardous locations heating, rely on the Ruffneck™ CX1 ProVector® for the most dependable, trouble-free service available. Explosion-proof air heaters were designed to satisfy the demanding requirements of the oil and gas well drilling industry. The harsh operating conditions of this application require the utmost in heater reliability.

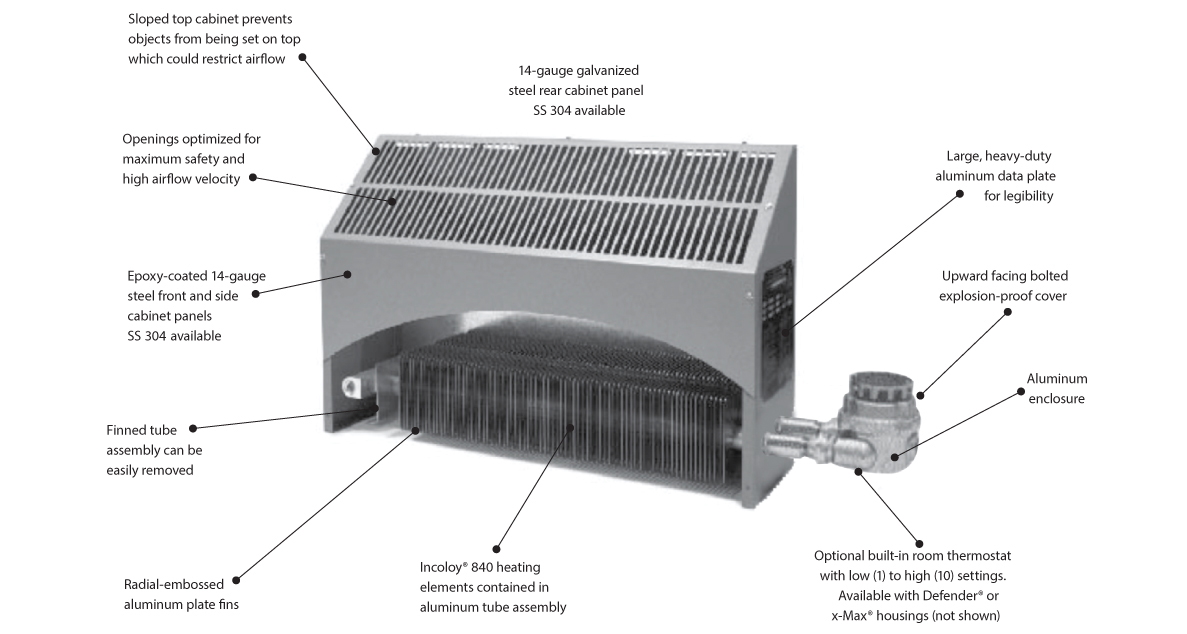

- Sloped-Top Cabinet

- No Exposed Copper or Brass

- High-Velocity Airflow

- 14GA Steel Cabinet

- Available Stainless-Steel Construction

- The Shortest Cabinet Lengths Available

- Optional Built-in Thermostat

- Incoloy® 840 Heating Elements

- Radial-Embossed Aluminum Plate Fins

- Galvanized Steel Mounting Brackets

- IP55 Moisture Ingress Protection

- Approvals - Groups A, B, C, D; IIA, IIB & IIC; Available

Reliability Is Not Optional.

CX1 heaters are UL certified for use in hazardous locations. Designed to satisfy the demanding requirements of the oil and gas well drilling industry.

Now That’s Smart!

Available Models

Ordering Information

| MODEL | kW (BTU/hr) | UNIT VOLTAGE (VOLTS) | BASIC UNIT | GAS GROUP IIB+H2 W/O T'STAT | GAS GROUP IIB W/ T'STAT | GAS GROUP IIC W/O T'STAT | GAS GROUP IIC W/ T'STAT | SUPPLY WIRE SIZE (AWG)*** | UNIT CURRENT (AMPS) | MAX. CIRCUIT FUSE (AMPs)* | CABINET LENGTH in(mm) | TEMP. CODE |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CX1-120160-012-T3 | 1.2 | 120 | • | • | • | • | • | 12 | 10 | 15 | 31.3 (796) | T3 |

| CX1-120160-018-T3 | 1.8 | 120 | • | • | • | • | • | 12 | 15 | 20 | 31.3 (796) | T3 |

| CX1-208160-012-T3 | 1.2 | 208 | • | • | • | • | • | 12 | 5.8 | 15 | 31.3 (796) | T3 |

| CX1-208160-018-T3 | 1.8 | 208 | • | • | • | • | • | 12 | 8.7 | 15 | 31.3 (796) | T3 |

| CX1-208160-036-T3** | 3.6 | 208 | • | • | • | • | • | 12 | 17.3 | 20 | 49.5 (1256) | T3 |

| CX1-208160-048-T2A | 4.8 | 208 | • | • | • | • | 8 | 23.1 | 25 | 49.5 (1256) | T2A | |

| CX1-208160-076-T2A | 7.6 | 208 | • | • | • | 8 | 36.5 | 40 | 59.5 (1511) | T2A | ||

| CX1-240160-012-T3 | 1.2 | 240 | • | • | • | • | • | 12 | 5 | 15 | 31.3 (796) | T3 |

| CX1-240160-018-T3 | 1.8 | 240 | • | • | • | • | • | 12 | 7.5 | 15 | 31.3 (796) | T3 |

| CX1-240160-036-T3** | 3.6 | 240 | • | • | • | • | • | 12 | 15 | 20 | 49.5 (1256) | T3 |

| CX1-240160-048-T2A | 4.8 | 240 | • | • | • | • | • | 10 | 20 | 25 | 49.5 (1256) | T2A |

| CX1-240160-076-T2A | 7.6 | 240 | • | • | • | 8 | 31.7 | 35 | 59.5 (1511) | T2A | ||

| CX1-277160-012-T3 | 1.2 | 277 | • | • | • | • | • | 12 | 4.3 | 15 | 31.3 (796) | T3 |

| CX1-277160-018-T3 | 1.8 | 277 | • | • | • | • | • | 12 | 6.5 | 15 | 31.3 (796) | T3 |

| CX1-277160-036-T3** | 3.6 | 277 | • | • | • | • | • | 12 | 13 | 15 | 49.5 (1256) | T3 |

| CX1-277160-048-T2A | 4.8 | 277 | • | • | • | • | • | 12 | 17.3 | 20 | 49.5 (1256) | T2A |

| CX1-277160-076-T2A | 7.6 | 277 | • | • | • | 8 | 27.4 | 30 | 59.5 (1511) | T2A | ||

| CX1-380160-0075-T3 | 0.75 | 380 | • | • | • | 12 | 2 | 15 | 31.3 (796) | T3 | ||

| CX1-380160-0113-T3 | 1.13 | 380 | • | • | • | 12 | 3 | 15 | 31.3 (796) | T3 | ||

| CX1-380160-012-T3 | 1.2 | 380 | • | • | • | • | • | 12 | 3.2 | 15 | 31.3 (796) | T3 |

| CX1-380160-018-T3 | 1.8 | 380 | • | • | • | • | • | 12 | 4.7 | 15 | 31.3 (796) | T3 |

| CX1-380160-0226-T2A | 2.26 | 380 | • | • | • | 12 | 5.9 | 15 | 31.3 (796) | T2A | ||

| CX1-380160-0301-T3 | 3.01 | 380 | • | • | • | 12 | 7.9 | 15 | 49.5 (1256) | T3 | ||

| CX1-380160-036-T3** | 3.6 | 380 | • | • | • | • | • | 12 | 9.5 | 15 | 49.5 (1256) | T3 |

| CX1-380160-0476-T2A | 4.76 | 380 | • | • | • | 10 | 12.5 | 15 | 59.5 (1511) | T2A | ||

| CX1-380160-048-T2A | 4.8 | 380 | • | • | • | • | • | 12 | 12.6 | 15 | 49.5 (1256) | T2A |

| CX1-380160-076-T2A | 7.6 | 380 | • | • | • | • | 10 | 20 | 25 | 59.5 (1511) | T2A | |

| CX1-400160-0083-T3 | 0.83 | 400 | • | • | • | 12 | 2.1 | 15 | 31.3 (796) | T3 | ||

| CX1-400160-012-T3 | 1.2 | 400 | • | • | • | • | • | 12 | 3 | 15 | 31.3 (796) | T3 |

| CX1-400160-0125-T3 | 1.25 | 400 | • | • | • | 12 | 3.1 | 15 | 31.3 (796) | T3 | ||

| CX1-400160-018-T3 | 1.8 | 400 | • | • | • | • | • | 12 | 4.5 | 15 | 31.3 (796) | T3 |

| CX1-400160-025-T2A | 2.5 | 400 | • | • | • | 12 | 6.3 | 15 | 31.3 (796) | T2A | ||

| CX1-400160-0333-T3 | 3.33 | 400 | • | • | • | 12 | 8.3 | 15 | 49.5 (1256) | T3 | ||

| CX1-400160-036-T3** | 3.6 | 400 | • | • | • | • | • | 12 | 9 | 15 | 49.5 (1256) | T3 |

| CX1-400160-048-T2A | 4.8 | 400 | • | • | • | • | • | 12 | 12 | 15 | 49.5 (1256) | T2A |

| CX1-400160-0528-T2A | 5.28 | 400 | • | • | • | 10 | 13.2 | 15 | 59.5 (1511) | T2A | ||

| CX1-400160-076-T2A | 7.6 | 400 | • | • | • | • | 10 | 19 | 20 | 59.5 (1511) | T2A | |

| CX1-415160-009-T3 | 0.9 | 415 | • | • | • | 12 | 2.2 | 15 | 31.3 (796) | T3 | ||

| CX1-415160-012-T3 | 1.2 | 415 | • | • | • | • | • | 12 | 2.9 | 15 | 31.3 (796) | T3 |

| CX1-415160-0135-T3 | 1.35 | 415 | • | • | • | 12 | 3.3 | 15 | 31.3 (796) | T3 | ||

| CX1-415160-018-T3 | 1.8 | 415 | • | • | • | • | • | 12 | 4.3 | 15 | 31.3 (796) | T3 |

| CX1-415160-0269-T2A | 2.69 | 415 | • | • | • | 12 | 6.5 | 15 | 31.3 (796) | T2A | ||

| CX1-415160-0359-T3 | 3.59 | 415 | • | • | • | 12 | 8.7 | 15 | 49.5 (1256) | T3 | ||

| CX1-415160-036-T3** | 3.6 | 415 | • | • | • | • | • | 12 | 8.7 | 15 | 49.5 (1256) | T3 |

| CX1-415160-048-T2A | 4.8 | 415 | • | • | • | • | • | 12 | 11.6 | 15 | 49.5 (1256) | T2A |

| CX1-415160-0568-T2A | 5.68 | 415 | • | • | • | 10 | 13.7 | 15 | 59.5 (1511) | T2A | ||

| CX1-415160-076-T2A | 7.6 | 415 | • | • | • | • | 10 | 18.3 | 20 | 59.5 (1511) | T2A | |

| CX1-480160-012-T3 | 1.2 | 480 | • | • | • | • | • | 12 | 2.5 | 15 | 31.3 (796) | T3 |

| CX1-480160-018-T3 | 1.8 | 480 | • | • | • | • | • | 12 | 3.8 | 15 | 31.3 (796) | T3 |

| CX1-480160-036-T3** | 3.6 | 480 | • | • | • | • | • | 12 | 7.5 | 15 | 49.5 (1256) | T3 |

| CX1-480160-048-T2A | 4.8 | 480 | • | • | • | • | • | 12 | 10 | 15 | 49.5 (1256) | T2A |

| CX1-480160-076-T2A | 7.6 | 480 | • | • | • | • | 10 | 15.8 | 20 | 59.5 (1511) | T2A | |

| CX1-600160-012-T3 | 1.2 | 600 | • | • | • | • | 12 | 2 | 15 | 31.3 (796) | T3 | |

| CX1-600160-018-T3 | 1.8 | 600 | • | • | • | • | 12 | 3 | 15 | 31.3 (796) | T3 | |

| CX1-600160-036-T3** | 3.6 | 600 | • | • | • | • | 12 | 6 | 15 | 49.5 (1256) | T3 | |

| CX1-600160-048-T2A | 4.8 | 600 | • | • | • | • | 12 | 8 | 15 | 49.5 (1256) | T2A | |

| CX1-600160-076-T2A | 7.6 | 600 | • | • | • | • | 12 | 12.7 | 15 | 59.5 (1511) | T2A |

Specifications

| NOMINAL WATTAGE (kW) | CABINET LENGTH ?B? | NET WEIGHT (lbs) | SHIPPING WEIGHT (lbs) |

|---|---|---|---|

| 0.75 - 2.69 & 3.6 (T2a) | 31.3 | 55.3 | 65 |

| 3.01 - 3.59 & 3.6 (T3) & 4.8 | 49.4 | 80.7 | 92.8 |

| 4.76, 5.28 - 7.6 | 59.5 | 95 | 105 |

Engineering Specs

Contractor shall supply and install CX1 Series explosion-proof heaters by King Electrical Mfg. Company. Heaters shall be of the wattage and voltage as indicated on the plans.

Hazardous Location Classifications

Without Built-in Thermostat: Defender® housing Class I, Div. 1 & 2, Groups B, C, & D; Zones 1 & 2, Groups IIA, IIB + H,x-Max® housing Class I, Div. 1 & 2, Groups A, B, C, & D; Zones 1 & 2, Groups IIA, IIB, & IIC.

With Built-in Thermostat: XCT Defender® thermostat: Class I, Div. 1 & 2, Groups C & D; Zones 1 & 2, Groups IIA & IIB XT thermostat: Class I, Div. 1 & 2, Groups A, B, C, & D; Zones 1 & 2, Groups IIA, IIB, & IIC.

Enclosure: Defender® housing is cast aluminum with bolt on cover. Groups IIB, x-Max® housing is extruded aluminum with two screwed on covers. The x-Max® housing offers IP55 moisture ingress protection. Groups IIC.

Mounting Brackets: Two 14-gauge (0.075” / 12 mm) galvanized steel brackets for standard cabinet. Stainless-steel brackets provided with optional stainless-steel cabinet.

Heating Elements: Two Incoloy® 840 sheathed elements

Temperature Code Rating: Temperature Code T2A – 536°F (280°C) or T3 – 392°F (200°C).

Temperature Limitations: Operational: -49°F to 104°F (-45°C to 40°C)Storage:-49°F to 176°F (-45°C to 80°C). Optional up to 300°F (149°C) available.

Cabinet Material: 14-gauge (0.075” / 1.90mm) epoxy coated steel with galvanized rear panel. Optional – 14-gauge 304 stainless-steel cabinet and mounting hardware available.