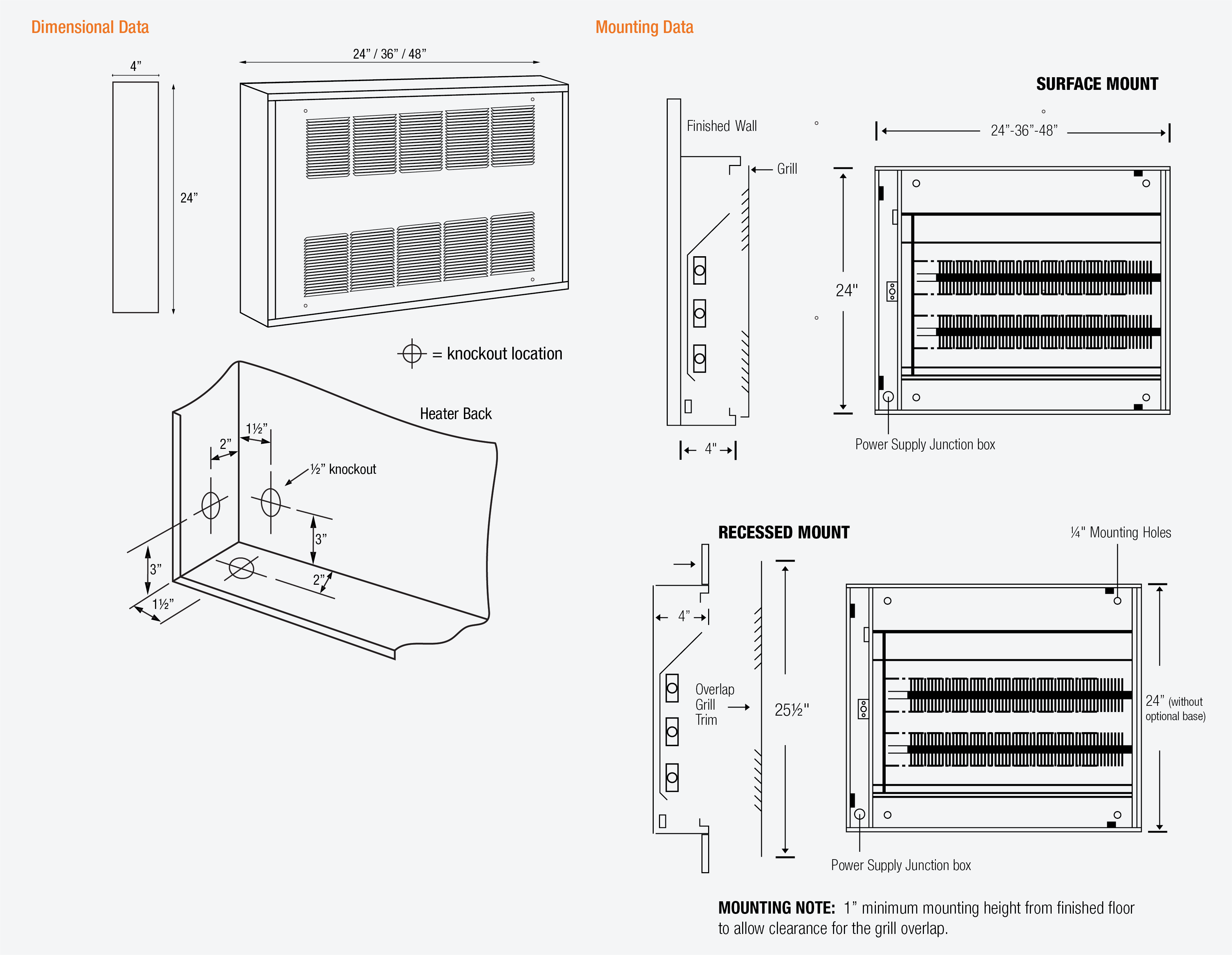

The King heavy-duty KCF cabinet heater can be placed almost anywhere. Typical uses are hall or entryways where a deep cabinet heater would be too intrusive. The slim design is great for schools, office, air terminals, auditoriums, apartments, restaurants, churches, factory’s, theaters and other locations where a clean impact resistant 18 gauge construction and entry way or comfort heating is needed. The KCF uses the time tested ceramic core heating elements that King developed over 50 years ago and have a very long life. Available in a slim 4”surface mount or the recess in wall installation. A sub-base is available when installing close to the floor to fill the gap. Thermostats, Contactors and Disconnect switches are available as options. Textured powder coated finish in an almond color. KCF model adds quiet tangential fans in the bottom of the cabinet to help move the heated air out of the cabinet. KCF model is not for residential use unless you add the Manual reset limit option.

Product Features

Impact Resistant and Reliable

Built to withstand years of high-traffic, with time-tested ceramic core heating elements that King developed over 50 years ago and have a very long life.

Now That’s Smart!

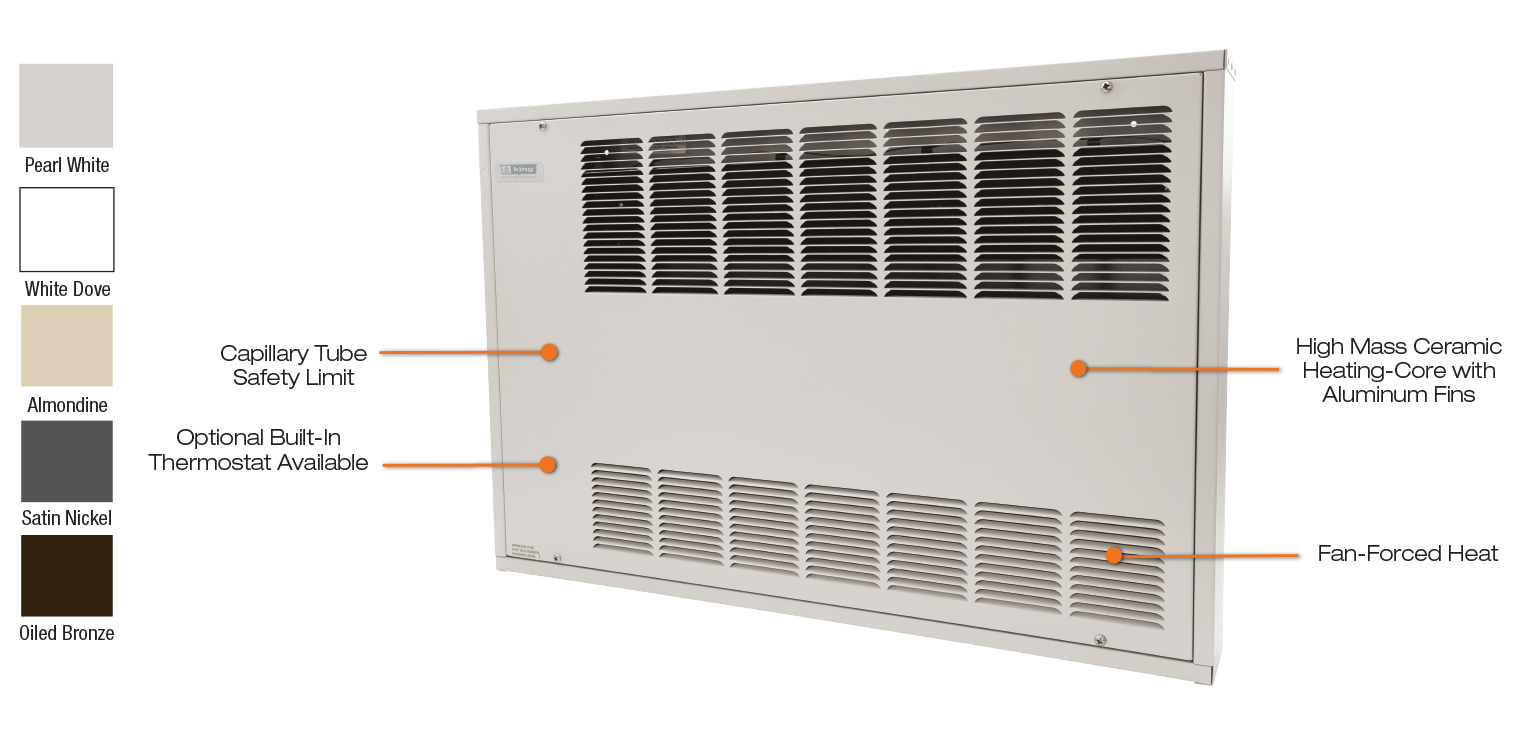

The Fan Circulates Warm Air Throughout The Room

The KCF model adds quiet tangential fans in the bottom of the cabinet to help move the heated air out of the cabinet and circulate it into the room.

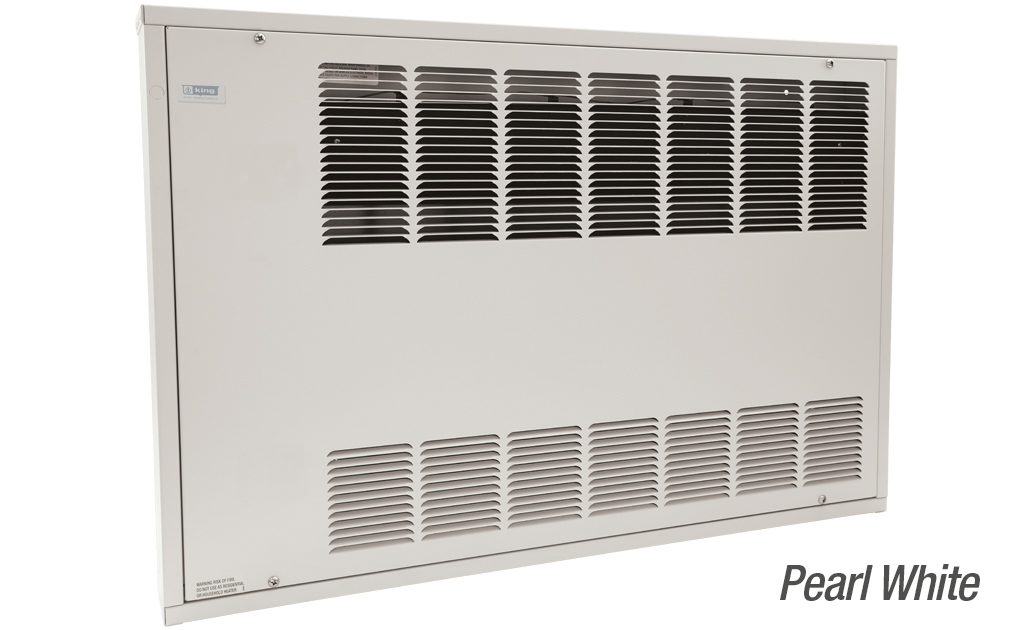

Freedom of Color

You know what it feels like when you walk into a well-designed building. Combine colors, materials, lighting, and now even designer heating fixtures to achieve the ambiance that fits your building. Choose from one of our dynamic designer colors, inspired by the architecture around us.

Pearl White – White Dove – Almondine – Satin Nickel – Oiled Bronze

Available Models

Step 1: Ordering Information - Single Phase Base Models

| BASE MODEL | VOLTS | WATTS | (1-PH) AMPS | BTUH(000) | CONTROL VOLTAGE | # of BLOWERS | CFM | LENGTH | SHIP WEIGHT lbs |

|---|---|---|---|---|---|---|---|---|---|

| KCF2-2010-1 | 208 | 1000 | 4.8 | 3.4 | 208V | 1 | 70 | 24" | 30 |

| KCF2-2020-1 | 208 | 2000 | 9.6 | 6.8 | 208V | 1 | 70 | 24" | 35 |

| KCF3-2030-1 | 208 | 3000 | 14.4 | 10.2 | 208V | 2 | 140 | 36" | 45 |

| KCF4-2040-1 | 208 | 4000 | 19.2 | 13.6 | 208V | 3 | 210 | 48" | 55 |

| KCF4-2050-1 | 208 | 5000 | 24 | 17 | 208V | 3 | 210 | 48" | 55 |

| KCF2-2410-1 | 240 | 1000 | 4.2 | 3.4 | 240V | 1 | 70 | 24" | 30 |

| KCF2-2420-1 | 240 | 2000 | 8.3 | 6.8 | 240V | 1 | 70 | 24" | 35 |

| KCF3-2430-1 | 240 | 3000 | 12.5 | 10.2 | 240V | 2 | 140 | 36" | 45 |

| KCF4-2440-1 | 240 | 4000 | 16.7 | 13.6 | 240V | 3 | 210 | 48" | 55 |

| KCF4-2450-1 | 240 | 5000 | 20.8 | 17 | 240V | 3 | 210 | 48" | 55 |

| KCF2-2710-1 | 277 | 1000 | 3.6 | 3.4 | 277V | 1 | 70 | 24" | 30 |

| KCF2-2720-1 | 277 | 2000 | 7.2 | 6.8 | 277V | 1 | 70 | 24" | 35 |

| KCF3-2730-1 | 277 | 3000 | 10.3 | 10.2 | 277V | 2 | 140 | 36" | 45 |

| KCF4-2740-1 | 277 | 4000 | 14.4 | 13.6 | 277V | 3 | 210 | 48" | 55 |

| KCF4-2750-1 | 277 | 5000 | 18 | 17 | 277V | 3 | 210 | 48" | 55 |

| KCF2-4810-1 | 480 | 1000 | 2.1 | 3.4 | 277V | 1 | 70 | 24" | 30 |

| KCF2-4820-1 | 480 | 2000 | 4.2 | 6.8 | 277V | 1 | 70 | 24" | 35 |

| KCF3-4830-1 | 480 | 3000 | 6.5 | 10.2 | 277V | 2 | 140 | 36" | 45 |

| KCF4-4840-1 | 480 | 4000 | 8.3 | 13.6 | 277V | 3 | 210 | 48" | 55 |

| KCF4-4850-1 | 480 | 5000 | 10.4 | 17 | 277V | 3 | 210 | 48" | 55 |

Step 1: Ordering Information - Three Phase Base Models

| BASE MODEL | VOLTS | WATTS | (3-PH) AMPS | BTUH(000) | CONTROL VOLTAGE | # of BLOWERS | CFM | LENGTH | SHIP WEIGHT lbs |

|---|---|---|---|---|---|---|---|---|---|

| KCF2-2010-3 | 208 | 1000 | 2.8 | 3.4 | 208V | 1 | 70 | 24" | 30 |

| KCF2-2020-3 | 208 | 2000 | 5.6 | 6.8 | 208V | 1 | 70 | 24" | 35 |

| KCF3-2030-3 | 208 | 3000 | 8.3 | 10.2 | 208V | 2 | 140 | 36" | 45 |

| KCF4-2040-3 | 208 | 4000 | 11.1 | 13.6 | 208V | 3 | 210 | 48" | 55 |

| KCF4-2050-3 | 208 | 5000 | 13.9 | 17 | 208V | 3 | 210 | 48" | 55 |

| KCF2-2410-3 | 240 | 1000 | 2.4 | 3.4 | 240V | 1 | 70 | 24" | 30 |

| KCF2-2420-3 | 240 | 2000 | 4.8 | 6.8 | 240V | 1 | 70 | 24" | 35 |

| KCF3-2430-3 | 240 | 3000 | 7.2 | 10.2 | 240V | 2 | 140 | 36" | 45 |

| KCF4-2440-3 | 240 | 4000 | 9.6 | 13.6 | 240V | 3 | 210 | 48" | 55 |

| KCF4-2450-3 | 240 | 5000 | 12 | 17 | 240V | 3 | 210 | 48" | 55 |

| KCF2-4810-3 | 480 | 1000 | 1.2 | 3.4 | 277V | 1 | 70 | 24" | 30 |

| KCF2-4820-3 | 480 | 2000 | 2.4 | 6.8 | 277V | 1 | 70 | 24" | 35 |

| KCF3-4830-3 | 480 | 3000 | 3.6 | 10.2 | 277V | 2 | 140 | 36" | 45 |

| KCF4-4840-3 | 480 | 4000 | 4.8 | 13.6 | 277V | 3 | 210 | 48" | 55 |

| KCF4-4850-3 | 480 | 5000 | 6 | 17 | 277V | 3 | 210 | 48" | 55 |

Step 2: Ordering Information - Add Suffix For Required Factory Installed Mounting Option

| ADD SUFFIX | DESCRIPTION |

|---|---|

| -R | Recessed Mount |

| -S | Surface Mount |

Step 3: Ordering Information - Add Suffix For Required Factory Installed Control Option

| ADD SUFFIX | DESCRIPTION |

|---|---|

| -T | 25 Amp Single Pole Thermostat w/Knob |

| -T2 | 25 Amp Double Pole Thermostat w/Knob |

| -TP | 25 Amp Tamperproof (slotted shaft), Single Pole |

| -RT | Provision For Remote Line Voltage Thermostat: Line Voltage Terminal Block Installed |

| -RT24 | Provision For Remote Low Voltage Thermostat: 24 Volt Contactor & Transformer Installed |

Step 4: Ordering Information - Add Suffix For Optional Factory Installed Control Options

| ADD SUFFIX | DESCRIPTION |

|---|---|

| -CX | Power Contactor (1-Phase Models Only) *Comes Standard on 3-Phase Models |

| -3PS | 3-Position Switch |

| -DS1 | Double Pole Disconnect Switch (1-Phase) |

| -DS3 | Three Pole Disconnect Switch (3-Phase) |

Step 5: Ordering Information - Add Suffix For Required Color Grill Option

| ADD SUFFIX | DESCRIPTION |

|---|---|

| -PW | Pearl White Color |

| -WD | White Dove Color |

| -AD | Almondine Color |

| -SN | Satin Nickel Color |

| -OB | Oiled Bronze Color |

Ordering Information - Optional Field Installed Accessories

| MODEL | UPC | DESCRIPTION |

|---|---|---|

| KC-SB-24 | 20319 | KC ACCY SUB-FLOOR BASE 24" WIDE, 2" TALL, 3" DEEP |

| KC-SB-36 | 20316 | KC ACCY SUB-FLOOR BASE 36" WIDE, 2" TALL, 3" DEEP |

| KC-SB-48 | 20317 | KC ACCY SUB-FLOOR BASE 48" WIDE, 2" TALL, 3" DEEP |

Engineering Specs

Contractor shall supply and install KCF Series cabinet heaters manufactured by King Electrical Mfg. Company. Heaters shall be of the wattage and voltage as indicated on the plans.

Construction: Heaters shall be constructed in 18 gauge galvanized Steel with epoxy powder-coated manufacturer’s standard finish. A louvered front cover with intake and outlet grille will protect element area and provide ample air flow to dissipate heated air.

Element: The superior performance comes from the proven technology of the ceramic thermal storage heater core. A 7/8″ diameter aluminum tube is filled with a special high density ceramic that stores the thermal energy. The oversized fins (4.875 in2) are made from durable (0.015″thick) high grade aluminum which produces better heat transfer than other elements. The benefit of the technology comes when the thermostat is turned off and the element continues to radiate heat. It also reduces temperature swings by heating and cooling more evenly. A fired refractory ceramic core with two large diameter Nickel Chromium coils attached with high temperature stainless connectors and stranded Nickel wire, terminated in a junctionbox.

Controls: A built-in thermal cutout shall automatically shut off the heater in case of overheating. A built-in thermostat for temperature control will have a range from 40°- 95°F and be of the high accuracy capillary tube-type. Disconnect switch and contactors will be provided if necessary.

Blower and Motor: Up to 3 tangential cylindrical blowers, delivering 70 CFM each, shall be driven by a shaded pole, permanently lubricated, C-frame type motor with impedance protection and sealed bearings. Motors shall be the same voltage as the heater. All 480V units use 277V motors and contactors. This requires a neutral connection.

Approvals: cULus