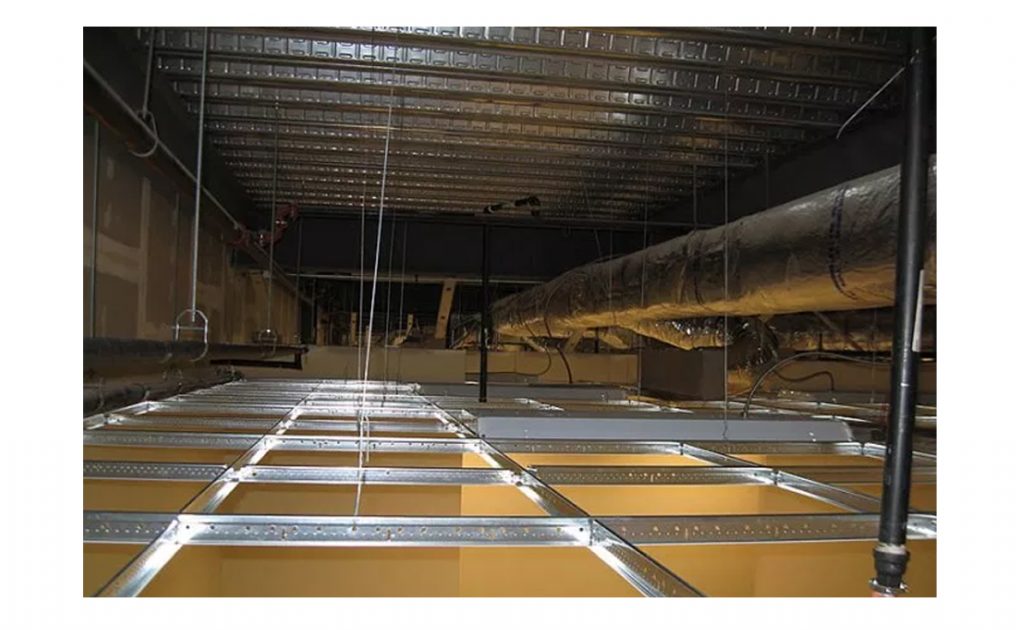

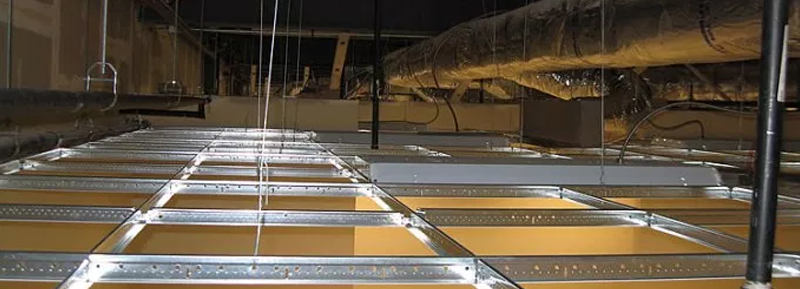

This large kW special application unit heater is approved for use in concealed areas of buildings. It is specifically designed for highrise and office buildings, factories, auto body shops, food processing plants, plating shops and machine shops. This heater may be installed in inaccessible areas such as between a concrete ceiling and a drop tile ceiling, in a open plenum or ducted system. The heater is designed to withstand a dirty, dusty, moist or mildly corrosive environment. Not intended for use where flammable vapors, gases, liquids or other combustibles are, or may be present.

- Spiral Finned Element

- High Mass Steel Fin Heat Exchanger

- Dual Inlet Blower

- Totally Enclosed Motor w/Variable Pitch Sheave

- N.E.M.A. 12 Construction

- Filter Racks

- 208/240/480 Volt

- Proportional Thermostat w/ Remote Sensor

- Fixed Louver Hood

- 12GA Steel Frame / 16GA Steel Enclosure

- Can Be Ducted

- 24V Control

- Proudly Made in the USA with U.S. & Global Materials

- 3-Year Limited Warranty

Product Features

Concealed Space Use - Zero Clearance

A special application heater approved for use in concealed areas of buildings such as an area between a finished ceiling and drop ceiling, in an open plenum or in a ducted system.

Learn more: What is a Plenum? (Read Tech Article)

Built Tough. Dirt, Dust, Plenum Space. No Problem.

Engineered to withstand dirty, dusty, moist or even mildly corrosive environments, and rated for zero clearance mounting against any surface.

Available Models

Base Model Chart

| MODEL | BTUH(000) | VOLTS | PHASE | KILO WATTS | RESISTIVE AMPS | No OF STAGES | KILO WATTS PER STAGE | WEIGHT lbs |

|---|---|---|---|---|---|---|---|---|

| CKL2050-3-4 | 170,650 | 208 | 3 | 50 | 139 | 4 | 12.5 | 600 |

| CKL2060-3-4 | 204,780 | 208 | 3 | 60 | 167 | 4 | 15 | 650 |

| CKL2070-3-6 | 238,909 | 208 | 3 | 70 | 195 | 6 | 11.7 | 650 |

| CKL2080-3-6 | 273,040 | 208 | 3 | 80 | 222 | 6 | 13.3 | 700 |

| CKL2090-3-6 | 307,170 | 208 | 3 | 90 | 250 | 6 | 15 | 700 |

| CKL20100-3-8 | 341,300 | 208 | 3 | 100 | 278 | 8 | 12.5 | 850 |

| CKL2450-3-4 | 170,650 | 240 | 3 | 50 | 120 | 4 | 12.5 | 650 |

| CKL2460-3-4 | 204,780 | 3 | 60 | 145 | 4 | 15 | 650 | |

| CKL2470-3-6 | 238,909 | 240 | 3 | 70 | 169 | 6 | 11.7 | 650 |

| CKL2480-3-6 | 273,040 | 240 | 3 | 80 | 193 | 6 | 13.3 | 700 |

| CKL2490-3-6 | 307,170 | 240 | 3 | 90 | 217 | 6 | 15 | 700 |

| CKL24100-3-8 | 341,300 | 240 | 3 | 100 | 241 | 8 | 12.5 | 850 |

| CKL24110-3-8 | 375,430 | 240 | 3 | 110 | 265 | 8 | 13.8 | 850 |

| CKL24120-3-8 | 409,560 | 240 | 3 | 120 | 289 | 8 | 15 | 850 |

| CKL4850-3-4 | 170,650 | 480 | 3 | 50 | 60 | 4 | 12.5 | 650 |

| CKL4860-3-4 | 204,780 | 480 | 3 | 60 | 72 | 4 | 15 | 650 |

| CKL4870-3-6 | 238,909 | 480 | 3 | 70 | 84 | 6 | 11.7 | 650 |

| CKL4880-3-6 | 273,040 | 480 | 3 | 80 | 96 | 6 | 13.3 | 700 |

| CKL4890-3-6 | 307,170 | 480 | 3 | 90 | 108 | 6 | 15 | 700 |

| CKL48100-3-8 | 341,300 | 480 | 3 | 100 | 120 | 8 | 12.5 | 850 |

| CKL48110-3-8 | 375,430 | 480 | 3 | 110 | 132 | 8 | 13.8 | 850 |

| CKL48120-3-8 | 409,560 | 480 | 3 | 120 | 145 | 8 | 15 | 850 |

| CKL48130-3-8 | 443,690 | 480 | 3 | 130 | 157 | 8 | 16.3 | 850 |

| CKL48140-3-8 | 477,820 | 480 | 3 | 140 | 169 | 8 | 17.5 | 900 |

| CKL48150-3-8 | 511,950 | 480 | 3 | 150 | 181 | 8 | 18.8 | 900 |

| CKL48160-3-8 | 546,080 | 480 | 3 | 160 | 193 | 8 | 20 | 950 |

| CKL48170-3-8 | 580,210 | 480 | 3 | 170 | 205 | 8 | 21.3 | 850 |

| CKL48180-3-8 | 614,340 | 480 | 3 | 180 | 217 | 8 | 22.5 | 1000 |

| CKL48190-3-8 | 648,470 | 480 | 3 | 190 | 229 | 8 | 23.8 | 1000 |

| CKL48200-3-8 | 682,600 | 480 | 3 | 200 | 241 | 8 | 25 | 1000 |

| CKL48210-3-8 | 716,730 | 480 | 3 | 210 | 253 | 8 | 26.3 | 1000 |

| CKL48220-3-8 | 750,860 | 480 | 3 | 220 | 265 | 8 | 27.5 | 1000 |

| CKL48230-3-8 | 784,990 | 480 | 3 | 230 | 277 | 8 | 28.8 | 1000 |

| CKL48240-3-8 | 819,120 | 480 | 3 | 240 | 289 | 8 | 30 | 1000 |

Required Factory Installed- Options

| MODEL | DESCRIPTION |

|---|---|

| -VF2 | Variable Frequency Drive 2HP - Variable Motor Speed |

| -VF3 | Variable Frequency Drive 3HP - Variable Motor Speed |

| -VF5 | Variable Frequency Drive 5HP - Variable Motor Speed |

| -VF7 | Variable Frequency Drive 7.5HP - Variable Motor Speed |

Optional Factory Installed - Options

| MODEL | DESCRIPTION |

|---|---|

| -SSR | Solid State Relays (SSR) for Modulating 1 Stage (Vernier Stage) |

| -PT | Proportional Thermostat and Remote Sensor to Control Discharge Temperature |

| -D1 | CKL 100 Amp Disconnect |

| -D2 | CKL 200 Amp Disconnect |

| -D4 | CKL 400 Amp Disconnect |

Engineering Specs

Contractor shall supply and install CKL Series plenum heaters manufactured by King Electrical Mfg. Company. Heaters shall be of the wattage and voltage as indicated on the plans.

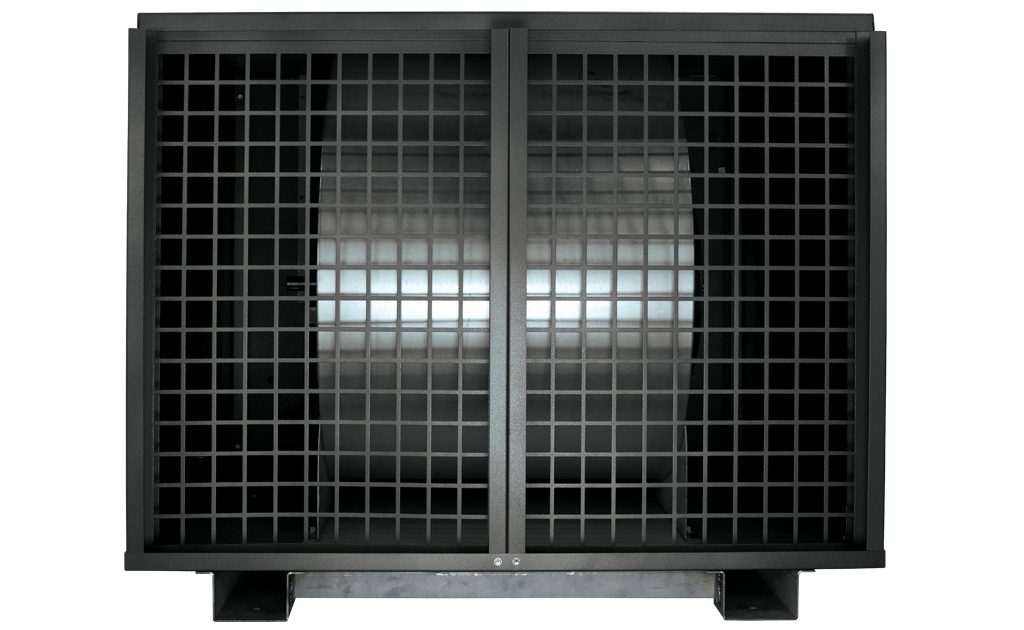

Construction: The heater frame is fabricated from 12 gauge high tensile electro-galvanized Steel forming a durable unibody cabinet. Enclosure panels are 16 gauge electro-galvanized Steel. Heater is finished with a rust inhibiting epoxy coating.

Air Outlet Louver: Fixed louvers

Intake and Discharge Screen: Heavy gauge Steel screen protects against foreign objects entering the heater. A filter is provided to prevent dirt and dust build-up in the heater.

Air Filter: Convenient access for replacement of standard filter. Filter not included.

Step Controller: The King CKL make up air unit is equipped with a 1 to 8 step controller and an optional vernier stage. This provides on/off control for each heating stage plus one fully modulating step when ordered with the optional Solid State Relays (SSR).

N.E.M.A. 12 Wiring Compartment: The wiring compartment is sealed with a 1⁄4″ high density polyurethane gasket. This provides excellent protection against moisture, dust and dirt from invading the electrical components and wiring. All optional control accessories are N.E.M.A. 12 rated.

Spiral Fin Elements: The metal sheath element is brazed with spiral fins then molded in to a coil configuration. This combination produces the best heat transfer while eliminating the potential for hot spots by positioning the element in the maximum airflow stream.

Easy Wiring: A large wiring compartment with easy access allows for quick installation.

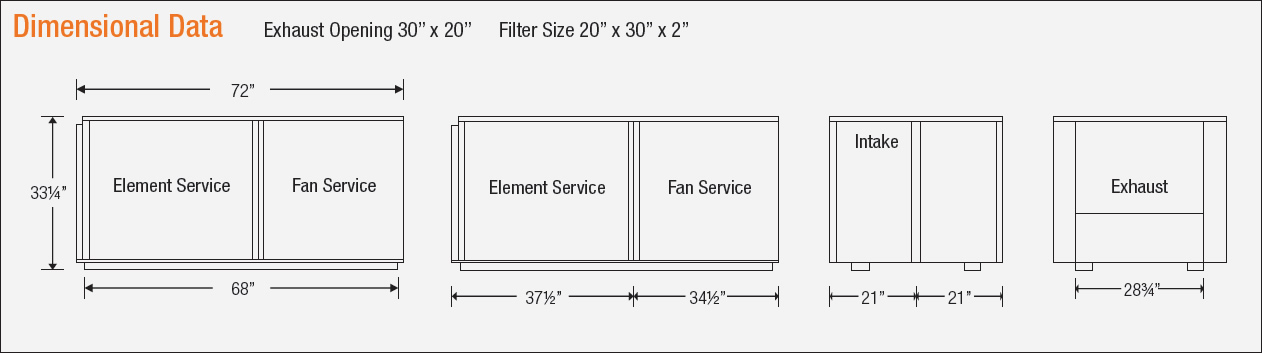

Mounting: The CKL heater comes with frame mounts.

Blower & Motor: Totally enclosed outdoor ball bearing fan motor. Permanently lubricated, class B insulation, auto-protected, permanent split capacitor and 60° C ambient. Large capacity dual inlet blower handles high static pressure and moves large air volume. Motor leads are enclosed in a sealtight raceway to prolong equipment life and reduce maintenance.

Air Intake Temperature Control: A built-in thermostat located at the intake blower is factory set at 100°F which prevents the heater from operating when the ambient temperature exceeds this limit. This will prevent the heater from wasting energy and is an extra measure of safety.

Auto-Reset Thermal Cutout: Power is disconnected from the heater if an overheated condition occurs. The element is re-energized automatically when the normal operating temperature returns.

Internal Controls: Magnetic contactors are standard on all units. A transformer is provided for 24 Volt control. This enables the customer to use a standard low voltage thermostat. Sub circuit fusing is provided when the heater ampacity exceeds 48 Amps to comply with UL standards. A fan delay is provided standard on all models to dissipate residual heat from the heating elements.

Variable Frequency Drive (VFD): Regulates the frequency that is fed to the motor, to run at the speed according to the demand needed.

Solid State Relay (SSR) Option: A solid state relay (SSR) enables high-precision, high-frequency temperature control by modulating the heat output as needed

to meet the current demand.

Proportional Thermostat Option: A proportional thermostat is designed to allow the appliance to heat more regularly and at low power, in order to minimize variations in the temperature of the room. The temperature of the room varies no more than ±0.9 °F from the requested temperature.

Disconnect Switch Option: Available with a 3-Pole non-fused disconnect with door interlocking feature and a padlock provision.

Approvals: ETL Certified to comply with standard for Heating and Cooling Equipment ANSI/UL 1995 fourth edition. Meets stringent City of Chicago codes for plenum use.