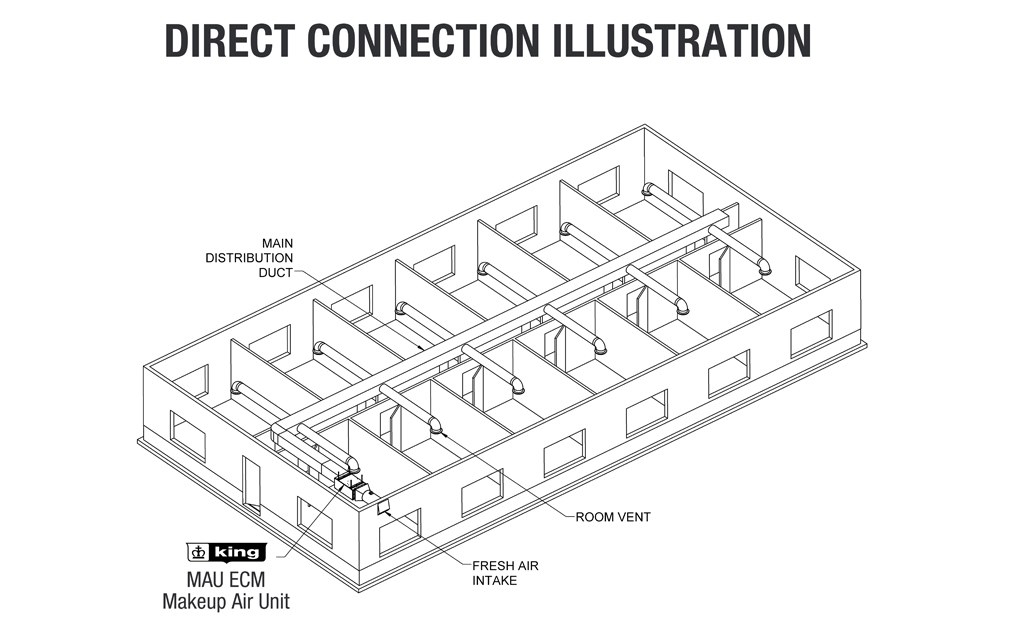

The King MAU Make-Up Air Unit is a plenum rated unit, designed to “make up” the air in your interior space that has been removed due to process exhaust fans. The building ventilation and the make-up air system work together to ensure the building pressure is maintained, while eliminating temperature fluctuations and a number of air quality issues. MAU preheats the incoming fresh air at the lowest cost, thus continuously providing comfortable ventilation throughout the building.

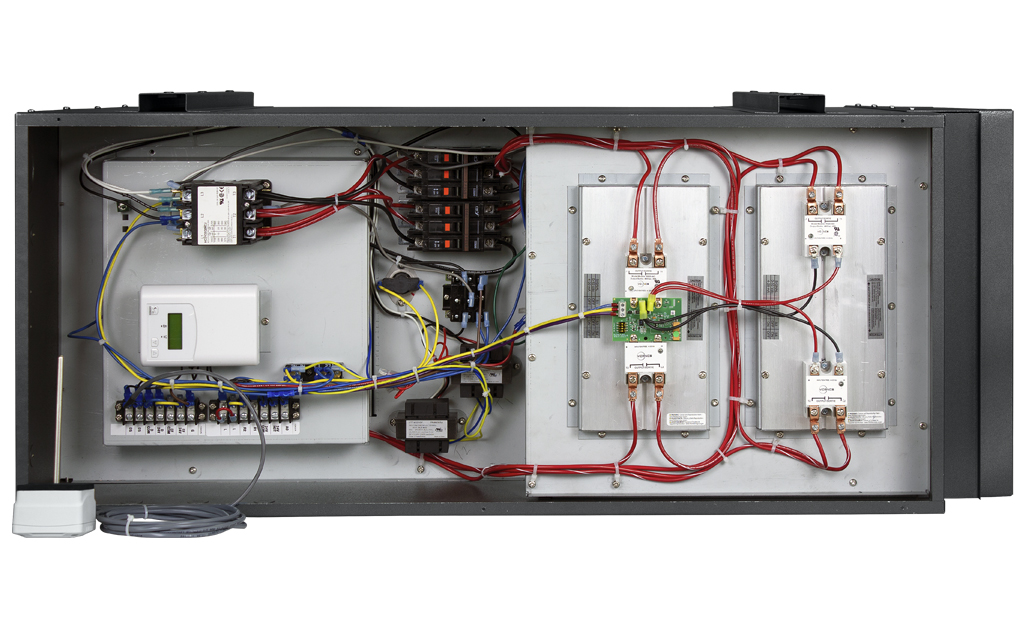

Featuring an energy efficient ECM motor, the MAU combines a fan driven fully modulating electric heating unit with a fresh air relay logic control circuit providing an extremely versatile all-in-one packaged unit.

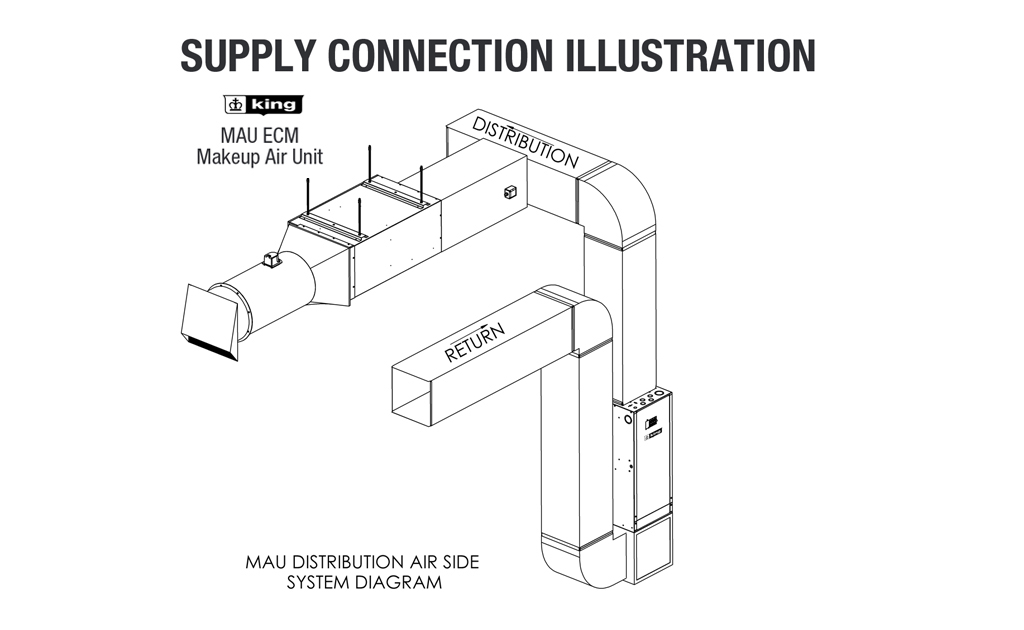

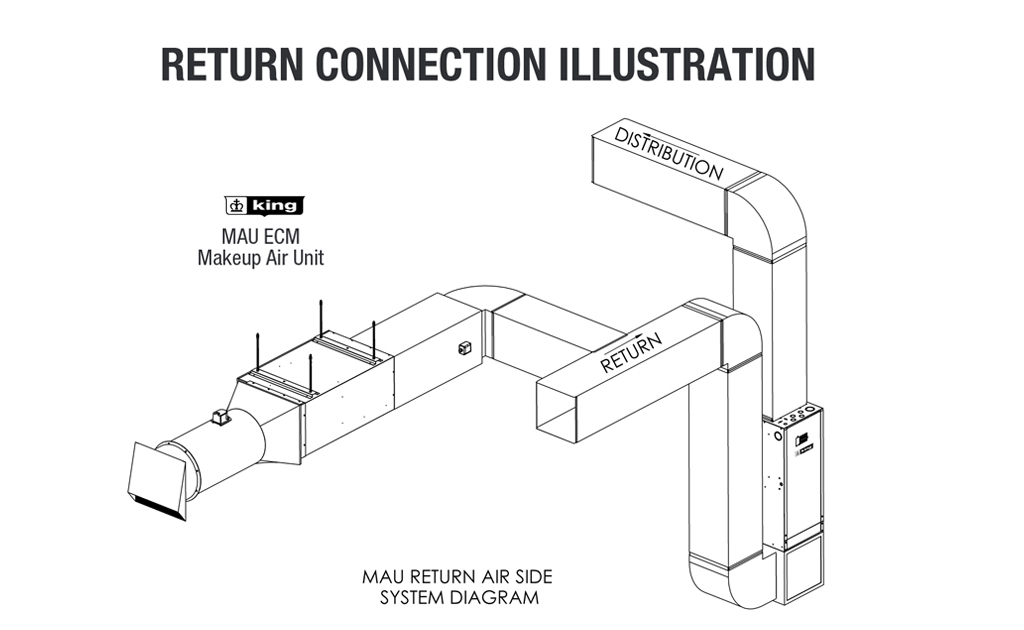

The MAU is approved for use in concealed areas of buildings such as an area between a finished ceiling and drop ceiling. It is designed to work with HVAC equipment to provide indoor air quality into a return side or supply side of the ductwork system or alternatively directly into the building space.

- Packaged, All-In-One Make Up Air Solution

- 700-1770 CFM @ 0.2” Static Pressure

- 3.8kW to 34.5kW Models Available

- Available in 208/240V/480V - Single & Three Phase

- Plenum Rated for Concealed Spaces

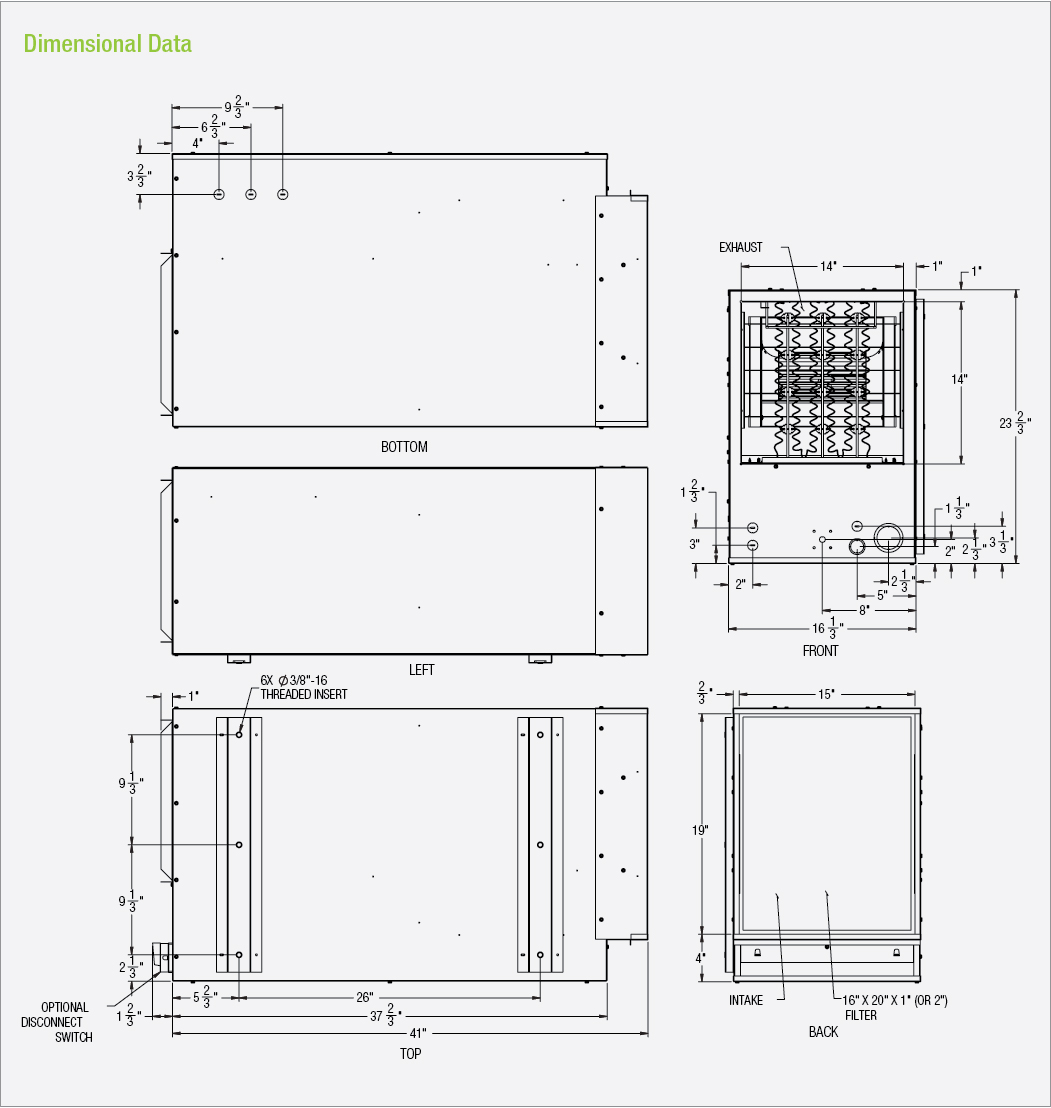

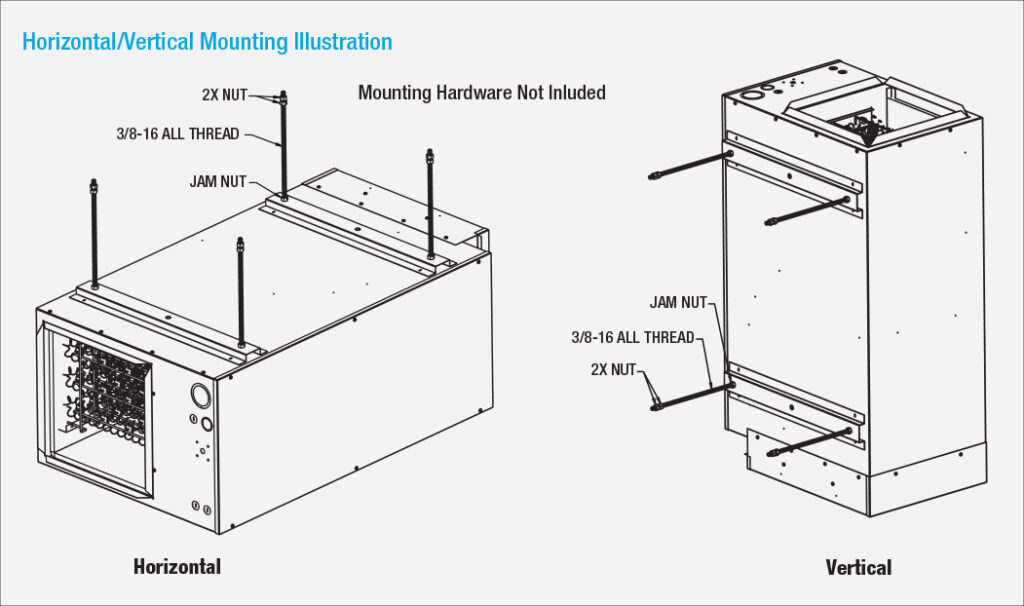

- Compact Design, Vertical or Horizontal Mounting

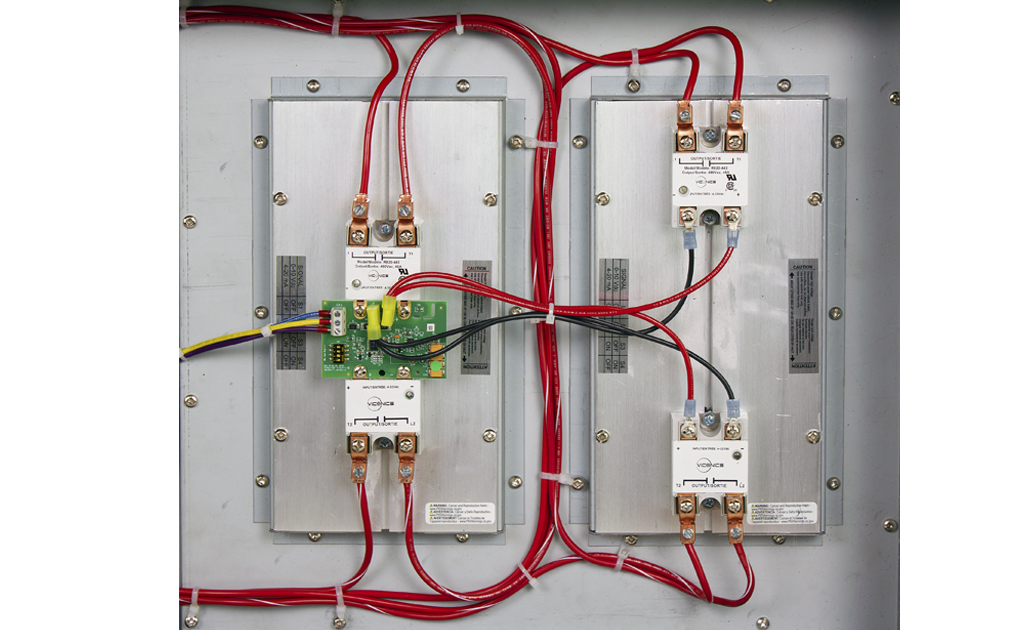

- Fully Modulating Electric Heat Using Solid State Relay (SSR) Technology

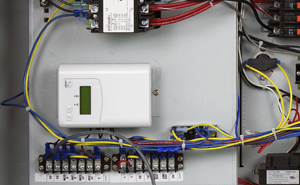

- Built-In Electronic Proportional Thermostat For Modulating Heat, 0-10V DC or 4-20ma

- Thermostat Can Be Relocated to Be Used as a Wall Mounted Room Thermostat

- 5 Motor Torque Settings for Field Adjustments to Meet CFM & Temperature Rise Requirements

- Energy efficient ECM motor, 1/3, 1/2HP & 3/4HP

- Detailed CFM/Static Pressure/Temperature Rise Tables to Design a Perfect Solution

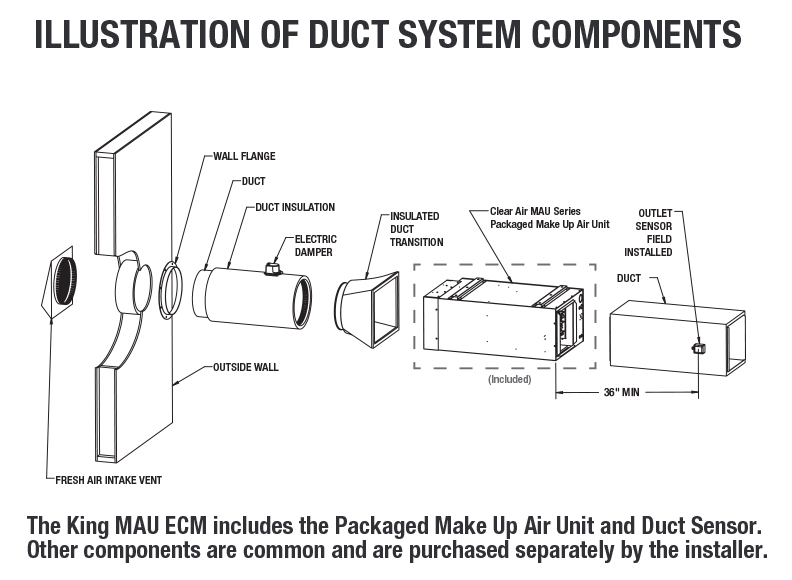

- Includes Field Installed Remote Duct Sensor For Precise Set Points

- Automatic Damper Control (damper purchased separately)

- Current Transformer Technology For Full Interlock With Exhaust Systems

- Relay Logic Control Circuit Enabling Control of Other Make-Up Air Components (Damper, Exhaust Fans, Outside Thermostat & Humidistat, Etc - purchased separately).

- Separate 40VA Control Power Transformer for Auxiliary Devices

- Side Access Panel For Easy Wiring & Maintenance

- Includes Lockout Circuit For BMS Compatibility

- Horizontal or Vertical Installation

- Compact Footprint

- 20-Gauge Electro Galvanized Steel Cabinet with Corrosion Resistant Finish

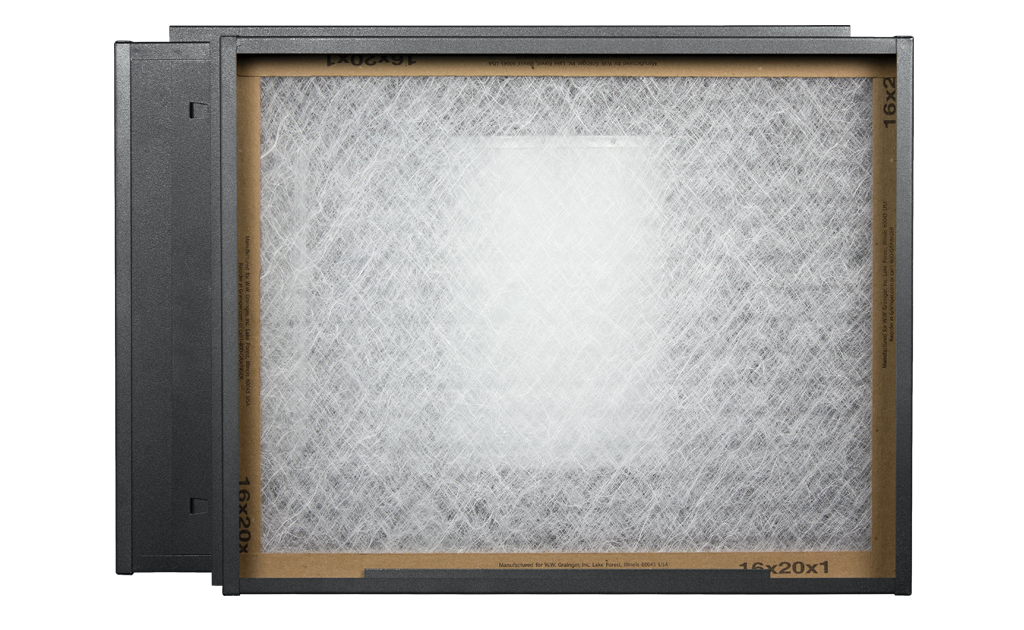

- Includes Filter Housing with 1" Thick Replaceable Air Filter. Compatible with up to 2" Thick Filter (purchased separately)

- Proudly Made in the USA with U.S. & Global Materials

- 3-Year Limited Warranty

Constant Comfortable Ventilation

Today’s airtight homes and offices beg for fresh air. Stale and humid air must be replaced by fresh air. During winter, the incoming fresh air is at too low a temperature to be comfortable and the MAU preheats the incoming air to your preset temperature.

Now That’s Smart!

The Relay Logic Control Circuit Means It Is Easily Tailored To Any Application

Relay logic control circuit enabling control of other make-up air components (damper, exhaust fans, outside thermostat and humidistat, etc).

Now That’s Smart!

ENERGY SAVINGS meets MAXIMUM FRESH AIR

The MAU features a state of the art electronically controlled motor for Maximum Energy Savings and Maximum Fresh Air.

Now That’s Smart!

Available Models

Ordering Information - Single Phase

| MODEL | VOLTS | KILOWATTS | BTU (000) | *AMPS | PHASE | # OF ELEMENTS | INTERNAL C/B | MOTOR HP | MOTOR FLA | WT. (lbs) | Purchase |

|---|---|---|---|---|---|---|---|---|---|---|---|

| MAU2004-1-ECM-SSR | 208V | 3.8 | 12.8 | 18 | -1Ph | 1 | 60 | 1/3 | 2.7 | 57 | Buy Now |

| MAU2005-1-ECM-SSR | 208V | 5 | 17.1 | 24 | -1Ph | 1 | 60 | 1/3 | 2.7 | 57 | Buy Now |

| MAU2008-1-ECM-SSR | 208V | 8 | 27.3 | 38 | -1Ph | 2 | 60 | 1/3 | 2.7 | 57 | Buy Now |

| MAU2010-1-ECM-SSR | 208V | 10 | 34.1 | 48 | -1Ph | 2 | 60+60 | 1/3 | 2.7 | 65 | Buy Now |

| MAU2012-1-ECM-SSR | 208V | 12 | 41 | 58 | -1Ph | 3 | 60+60 | 1/3 | 2.7 | 74 | Buy Now |

| MAU2015-1-ECM-SSR | 208V | 15 | 51.2 | 72 | -1Ph | 3 | 60+60 | 1/3 | 2.7 | 74 | Buy Now |

| MAU2018-1-ECM-SSR | 208V | 17.3 | 58.9 | 83 | -1Ph | 4 | 60+60 | 1/3 | 3.9 | 76 | Buy Now |

| MAU2020-1-ECM-SSR | 208V | 20 | 68.3 | 96 | -1Ph | 4 | 60+60 | 1/2 | 3.9 | 76 | |

| MAU2025-1-ECM-SSR | 208V | 25 | 85.3 | 120 | -1Ph | 5 | 60+60+60 | 1/2 | 6 | 81 | |

| MAU2030-1-ECM-SSR | 208V | 30 | 102.4 | 144 | -1Ph | 6 | 60+60+60 | 3/4 | 6 | 85 | |

| MAU2404-1-ECM-SSR | 240V | 4 | 13.7 | 17 | -1Ph | 1 | 60 | 1/3 | 2.9 | 57 | Buy Now |

| MAU2405-1-ECM-SSR | 208V | 5 | 17.1 | 21 | -1Ph | 1 | 60 | 1/3 | 2.9 | 57 | Buy Now |

| MAU2408-1-ECM-SSR | 240V | 8 | 27.3 | 33 | -1Ph | 2 | 60 | 1/3 | 2.9 | 57 | Buy Now |

| MAU2410-1-ECM-SSR | 240V | 10 | 34.1 | 42 | -1Ph | 2 | 60 | 1/3 | 2.9 | 65 | Buy Now |

| MAU2412-1-ECM-SSR | 240V | 12 | 41 | 50 | -1Ph | 2 | 60 | 1/3 | 2.9 | 74 | Buy Now |

| MAU2415-1-ECM-SSR | 240V | 15 | 51.2 | 63 | -1Ph | 3 | 60+60 | 1/3 | 2.9 | 74 | Buy Now |

| MAU2418-1-ECM-SSR | 240V | 17.3 | 58.9 | 72 | -1Ph | 3 | 60+60 | 1/3 | 2.9 | 74 | Buy Now |

| MAU2420-1-ECM-SSR | 240V | 20 | 68.3 | 83 | -1Ph | 4 | 60+60 | 1/2 | 4.2 | 76 | Buy Now |

| MAU2425-1-ECM-SSR | 240V | 25 | 85.3 | 104 | -1Ph | 5 | 60+60+60 | 1/2 | 4.2 | 81 | |

| MAU2430-1-ECM-SSR | 240V | 30 | 102.4 | 125 | -1Ph | 6 | 60+60+60 | 3/4 | 6.2 | 85 | |

| MAU2435-1-ECM-SSR | 240V | 34.5 | 117.7 | 144 | -1Ph | 6 | 60+60+60 | 3/4 | 6.2 | 85 | |

| MAU4804-1-ECM-SSR | 480V | 4 | 13.7 | 8 | -1Ph | 1 | NO | 1/3 | 0.8 | 57 | Buy Now |

| MAU4805-1-ECM-SSR | 480V | 5 | 17.1 | 10 | -1Ph | 1 | NO | 1/3 | 0.8 | 57 | Buy Now |

| MAU4808-1-ECM-SSR | 480V | 8 | 27.3 | 17 | -1Ph | 2 | NO | 1/3 | 0.8 | 57 | Buy Now |

| MAU4810-1-ECM-SSR | 480V | 10 | 34.1 | 21 | -1Ph | 2 | NO | 1/3 | 0.8 | 65 | Buy Now |

| MAU4812-1-ECM-SSR | 480V | 12 | 41 | 25 | -1Ph | 3 | NO | 1/3 | 0.8 | 74 | Buy Now |

| MAU4815-1-ECM-SSR | 480V | 15 | 51.2 | 31 | -1Ph | 3 | NO | 1/3 | 0.8 | 74 | Buy Now |

| MAU4818-1-ECM-SSR | 480V | 17.3 | 58.9 | 36 | -1Ph | 3 | NO | 1/3 | 0.8 | 74 | Buy Now |

| MAU4820-1-ECM-SSR | 480V | 20 | 68.3 | 42 | -1Ph | 4 | NO | 1/2 | 1.2 | 76 | Buy Now |

| MAU4825-1-ECM-SSR | 480V | 25 | 85.3 | 52 | -1Ph | 5 | NO | 1/2 | 1.2 | 81 | Buy Now |

| MAU4830-1-ECM-SSR | 480V | 30 | 102.4 | 63 | -1Ph | 6 | NO | 3/4 | 1.7 | 85 | Buy Now |

| MAU4835-1-ECM-SSR | 480V | 34.5 | 117.7 | 72 | -1Ph | 6 | NO | 3/4 | 1.7 | 85 | Buy Now |

Ordering Information - Three Phase

| MODEL | VOLTS | KILOWATTS | BTU (000) | *AMPS | PHASE | # OF ELEMENTS | INTERNAL C/B | MOTOR HP | MOTOR FLA | WT. (lbs) | Purchase |

|---|---|---|---|---|---|---|---|---|---|---|---|

| MAU2005-3-ECM-SSR | 208V | 5 | 17.1 | 14 | -3Ph | 1 | 60 | 1/3 | 2.7 | 57 | Buy Now |

| MAU2007-3-ECM-SSR | 208V | 7.5 | 25.6 | 21 | -3Ph | 2 | 60 | 1/3 | 2.7 | 57 | |

| MAU2010-3-ECM-SSR | 208V | 10 | 34.1 | 28 | -3Ph | 2 | 60 | 1/3 | 2.7 | 65 | Buy Now |

| MAU2012-3-ECM-SSR | 208V | 12.5 | 42.7 | 34 | -3Ph | 3 | 60 | 1/3 | 2.7 | 74 | |

| MAU2015-3-ECM-SSR | 208V | 15 | 51.2 | 42 | -3Ph | 3 | 60 | 1/3 | 2.7 | 74 | Buy Now |

| MAU2020-3-ECM-SSR | 208V | 20 | 68.3 | 56 | -3Ph | 4 | 60 | 1/2 | 3.9 | 76 | Buy Now |

| MAU2025-3-ECM-SSR | 208V | 25 | 85.3 | 69 | -3Ph | 5 | 60+60 | 3/4 | 6 | 81 | Buy Now |

| MAU2030-3-ECM-SSR | 208V | 30 | 102.4 | 83 | -3Ph | 6 | 60+60 | 3/4 | 6 | 85 | Buy Now |

| MAU2405-3-ECM-SSR | 240V | 5 | 17.1 | 12 | -3Ph | 1 | 60 | 1/3 | 2.9 | 57 | Buy Now |

| MAU2410-3-ECM-SSR | 240V | 10 | 34.1 | 24 | -3Ph | 2 | 60 | 1/3 | 2.9 | 65 | Buy Now |

| MAU2412-3-ECM-SSR | 240V | 12 | 41 | 29 | -3Ph | 3 | 60 | 1/3 | 2.9 | 65 | |

| MAU2415-3-ECM-SSR | 240V | 15 | 51.2 | 36 | -3Ph | 3 | 60 | 1/3 | 2.9 | 74 | Buy Now |

| MAU2418-3-ECM-SSR | 240V | 17.3 | 58.9 | 42 | -3Ph | 3 | 60 | 1/3 | 2.9 | 74 | |

| MAU2420-3-ECM-SSR | 240V | 20 | 68.3 | 48 | -3Ph | 4 | 60 | 1/2 | 4.2 | 76 | Buy Now |

| MAU2425-3-ECM-SSR | 240V | 25 | 85.3 | 60 | -3Ph | 5 | 60 | 1/2 | 4.2 | 81 | Buy Now |

| MAU2430-3-ECM-SSR | 240V | 30 | 102.4 | 72 | -3Ph | 6 | 60+60 | 3/4 | 6.2 | 85 | Buy Now |

| MAU2435-3-ECM-SSR | 240V | 34.5 | 117.7 | 83 | -3Ph | 6 | 60+60 | 3/4 | 6.2 | 85 | Buy Now |

| MAU4805-3-ECM-SSR | 480V | 5 | 17.1 | 6 | -3Ph | 1 | NO | 1/3 | 0.8 | 57 | Buy Now |

| MAU4810-3-ECM-SSR | 480V | 10 | 34.1 | 12 | -3Ph | 2 | NO | 1/3 | 0.8 | 65 | Buy Now |

| MAU4815-3-ECM-SSR | 480V | 15 | 51.2 | 18 | -3Ph | 3 | NO | 1/3 | 0.8 | 74 | Buy Now |

| MAU4818-3-ECM-SSR | 480V | 17.3 | 58.9 | 21 | -3Ph | 3 | NO | 1/3 | 0.8 | 74 | |

| MAU4820-3-ECM-SSR | 480V | 20 | 68.3 | 24 | -3Ph | 4 | NO | 1/2 | 1.2 | 76 | Buy Now |

| MAU4825-3-ECM-SSR | 480V | 25 | 85.3 | 30 | -3Ph | 5 | NO | 1/2 | 1.2 | 81 | Buy Now |

| MAU4830-3-ECM-SSR | 480V | 30 | 102.4 | 36 | -3Ph | 6 | NO | 3/4 | 1.7 | 85 | Buy Now |

| MAU4835-3-ECM-SSR | 480V | 34.5 | 117.7 | 42 | -3Ph | 6 | NO | 3/4 | 1.7 | 85 | Buy Now |

Ordering Information - Accessories

| MODEL | UPC | DESCRIPTION | WEIGHT(lbs.) | Purchase |

|---|---|---|---|---|

| KFS-DT | 20186 | Transition from 14" x 14" Outlet to 12" round, discharge side | 2.5 | Buy Now |

| RIBU1C | 33347 | Fan Relay 10 Amp SPDT w/10-30 Vac/dc/120 Vac Coil | ||

| CS120AF | 33444 | Current Sensor, 120V, Solid State | 1 |

Ordering Information - Controls Accessories

| Model | UPC | DESCRIPTION | Weight (Lbs.) |

|---|---|---|---|

| DFC120V | 33445 | Digital Fan Control, 5 Modes of Operation - 120V (Requires -CR120 Factory Installed Option) | 1 |

Ordering Information - External Mount Duct Fans Accessories

| MODEL | UPC | VOLTS | DESCRIPTION | Weight (Lbs.) |

|---|---|---|---|---|

| EXT100A | 33446 | 120 | External Mount Duct Fan 4", 118 cfm | 11.6 |

| EXT100B | 33447 | 120 | External Mount Duct Fan 4", 177 cfm | 11.6 |

| EXT150A | 33448 | 120 | External Mount Duct Fan 6", 227 cfm | 11.6 |

| EXT150B | 33449 | 120 | External Mount Duct Fan 6", 396 cfm | 18 |

| EXT200A | 33450 | 120 | External Mount Duct Fan 8", 445 cfm | 18 |

| EXT200B | 33451 | 120 | External Mount Duct Fan 8", 420 cfm | 19 |

Ordering Information - Centrifugal In-Line Fan Accessories

| MODEL | UPC | VOLTS | DESCRIPTION | Weight (Lbs.) |

|---|---|---|---|---|

| MBI100 | 33452 | 120 | Centrifugal In-Line Fan 4", 147 cfm | 12 |

| MBI125 | 33453 | 120 | Centrifugal In-Line Fan 5", 173 cfm | 12 |

| MBI125/100 | 33454 | 120 | Centrifugal In-Line Fan 5"-4", 232 cfm | 12 |

| MBI150 | 33455 | 120 | Centrifugal In-Line Fan 6", 221 cfm | 16 |

| MBI150/125 | 33456 | 120 | Centrifugal In-Line Fan 6"-5", 290 cfm | 16 |

Ordering Information - Ventilation Grills Accessories

| MODEL | UPC | DESCRIPTION | Weight (Lbs.) |

|---|---|---|---|

| AG150 | 33457 | AeroGrill 6" | 5 |

| AG150-C | 33458 | AeroGrill 6", Collar | 6 |

| AG150-CD | 33459 | AeroGrill 6", Collar, Damper | 7 |

| GR100 | 33460 | Adjustable Grill 4", Collar | 1 |

| GR150 | 33461 | Adjustable Grill 6", Collar | 1 |

| GR200 | 33462 | Adjustable Grill 8", Collar | 2 |

| GR100-6PK | 33463 | Adjustable 4", Collar-6 pcs | 4 |

| GR150-6PK | 33464 | Adjustable 6", Collar-6 pcs | 6 |

Ordering Information - Options

| ADD SUFFIX: | DESCRIPTION |

|---|---|

| -1/2HP | 1/2HP Motor & Blower - 4kW to 17.25kW |

| -3/4HP | 3/4HP Motor & Blower - 4kW to 25kW |

Ordering Information - Factory Installed Options

| ADD SUFFIX: | DESCRIPTION |

|---|---|

| -CR120 | 10 Amp Relay, SPDT w/10-30 Vac/dc/120 Vac Coil that switches the 24V heater control circuit |

| -DS32 | 32 Amp, 3-Pole Disconnect Switch w/ Padlock Provision |

| -DS63 | 63 Amp, 3-Pole Disconnect Switch w/ Padlock Provision |

| -DS100 | 100 Amp, 3-Pole Disconnect Switch w/ Padlock Provision |

Engineering Specs

Engineering Specifications

Contractor shall furnish and install King MAU Make-Up Air Unit manufactured by King Electrical Manufacturing.

Motor: Direct drive high efficiency, thermally protected, permanently lubricated ECM motor, no belts to adjust or maintain.

Motor Terminal: Clear Air shall have a 5-point terminal block to easily field adjust the motor torque setting of the ECM motor.

Modulating Heat: 100% fully modulating heating control through Solid State Relay (SSR) technology. The SSR relays shall be mounted in the blower compartment to allow the free flow of incoming air to cool the heat sinks.

Thermostat: MAU shall be controlled by an electronic proportional thermostat using a 0 to 10VDC of 4 to 20ma signal. The inbuilt thermostat

can be removed and relocated to room and used as a wall mounted thermostat.

Duct Sensor: MAU shall be provided with a field installed duct sensor, type 2 NTC thermistor, 10K ohms.

Heating Elements: Quick heating, long life Ni-Chrome elements supported by a steel frame and insulated with ceramic holders.

LV Terminal Block: All low voltage wires are terminated at a 14-point block with factory side quick connects and field side screw terminals.

Control Circuit: MAU shall have a relay logic control circuit providing a dedicated 24V power supply that is switched to activate external devices such as:

a damper, exhaust fan, etc.

Lockout Circuit: MAU shall have a lockout circuit for auxiliary devices such as an outside thermostat or humidistat to prevent the Clear Air system from turning on

unless predetermined conditions are met, as well as BMS Compatibility.

Overcurrent Protection: MAU shall have a 24V high temperature limit circuit wired in series to protect each individual heating element. In addition, it shall have one electrically held manual limit monitoring the condition of entire unit. If tripped, this limit must be manually reset by shutting off the power, waiting several minutes and then turning the power back on. This provides an extra level of overheating protection to the unit.

Enclosure: MAU shall be constructed from 20GA electrogalvanized sheet metal of welded construction and finished with a corrosion resistant gray finished. Unpainted sheet steel is not acceptable. Access to the wiring compartment shall be from the side for easy wiring and maintenance. The unit shall have welded brackets with 6 – 3/8” weld nuts for sturdy mounting either vertically or horizontally. Provide both Line voltage and Low voltage knockouts to speed contractor installation. Provide knockouts for an optional disconnect.

Filter: Includes Filter Housing with 1″ Thick Replaceable Air Filter. Compatible with up to 2″ Thick Filter (purchased separately)

Blower: Centrifugal dual inlet blower shall be used, axial fans not permitted. Blower shall be rigidly mounted to the enclosure with internal welded mounting brackets.

Optional Disconnect: The unit shall have the option to mount an internal Supply Power Disconnect.

Approvals: UL: MAU shall be Underwriters Laboratory (UL) approved and labeled. Meets UL1995 standards and stringent City of Chicago codes for plenum use.